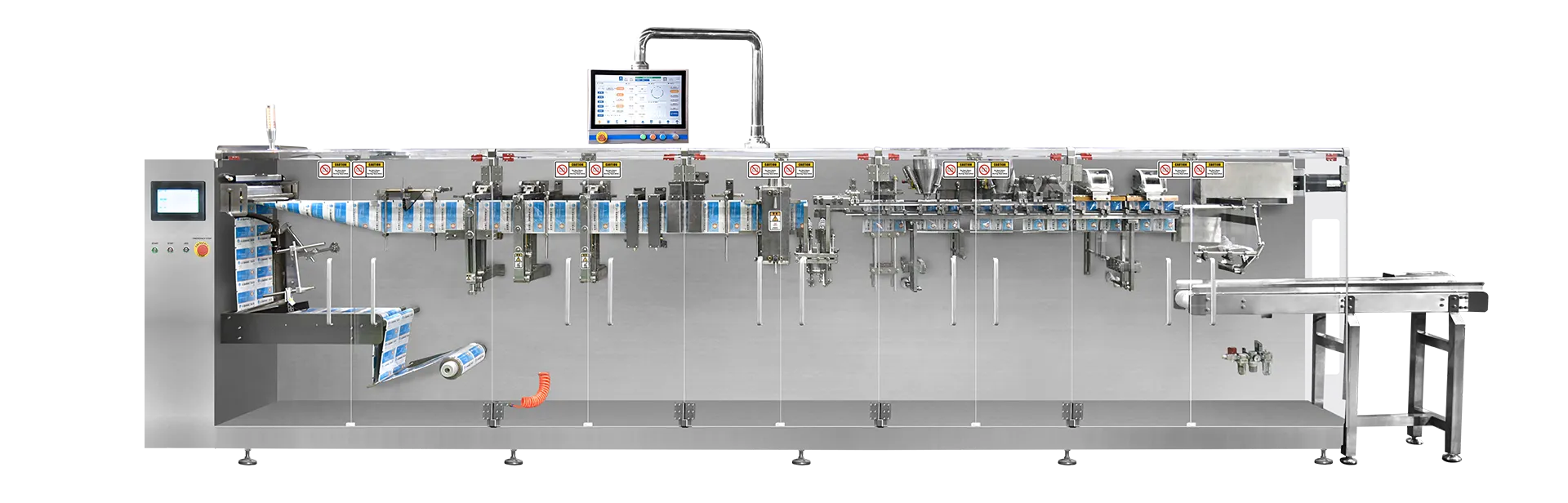

S:Sachet Packing Machine

The three-side or four-side roll film horizontal packaging machine is one of the most versatile packaging equipment. Its horizontal layout feature gives it an irreplaceable advantage when handling specific products. Its technical maturity and flexibility are extremely high.

Add the coding function

Edge sealing and

cooling, smooth and

free of wrinkles

Customizable cut

pouch shape

Double filling device,

more efficient

Servo bagging, with

stable travel distance

Servo WB,with stable

travel, precise filling, and

stable edge sealing.

Core Strengths:

Friendly to products: Horizontal push-in filling, perfectly protecting fragile and deformable products.

Various packaging forms: Can easily achieve three-sided sealing, four-sided sealing, punching, bundling and other packaging forms.

High flexibility: Quickly change product specifications and film rolls to adapt to market changes.

High efficiency: Production speed is high, up to hundreds of packages per minute.

Low cost: The cost of film rolls is lower than pre-made bags, with high cost-effectiveness.

Application fields (extremely wide):

Food: cookies, wafers, pastries, chocolate, ice cream, candies, frozen foods, seasonings, etc.

Cosmetics: laundry detergent, shampoo, skin care products, wipes, etc.

Medicine: pills, powder, liquid medicine, capsules, etc.

Health supplements: granules, protein powder, etc.

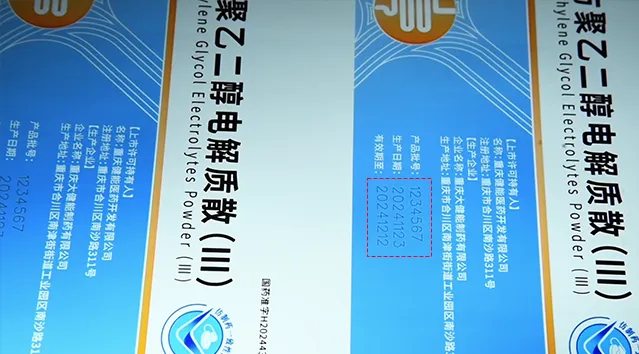

Coding function

The coding function can be enabled, allowing the batch number, date, expiration date, etc. of the packaged products to be coded.

Self-sealing device

The horizontal roll film packaging machine can customize the shape of the self-sealing device, which can be used for packaging in the form of diamonds, arcs, blade shapes, etc.

Industries

Granular

Liquid

Powdery

Mixed