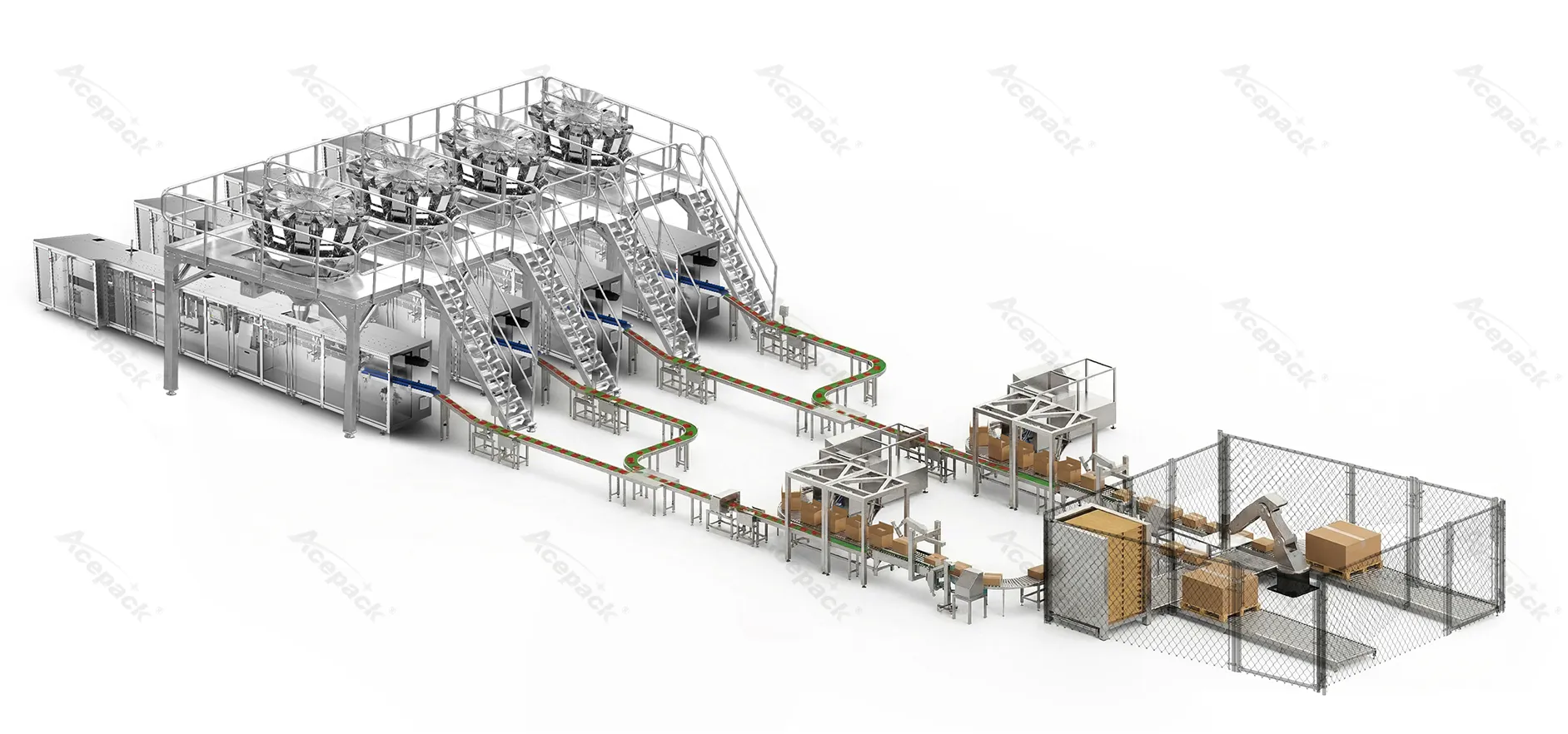

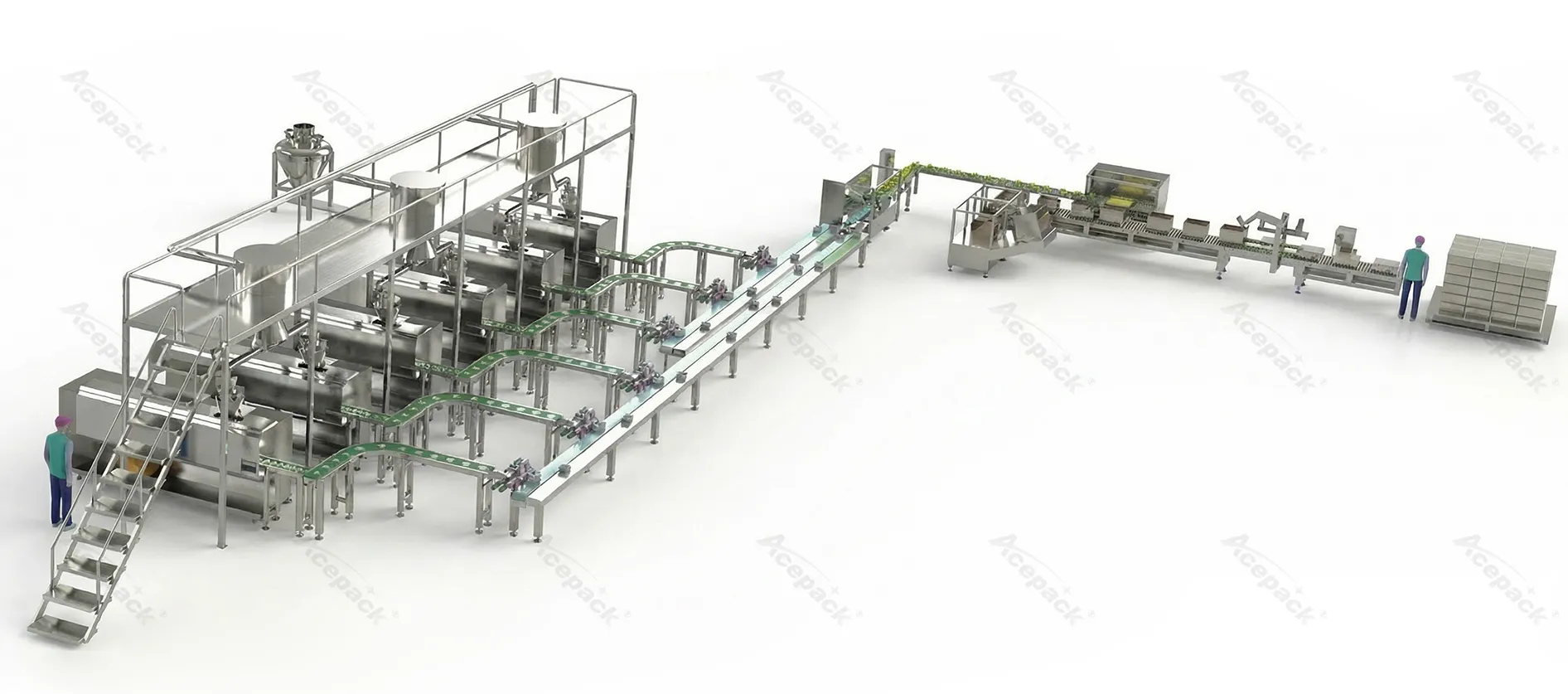

Whole Packaging Line

The horizontal film packaging line integrates the unpacking machine, packing machine, sealing machine, re-inspection machine and palletizing equipment on the basis of the original automated packaging system, forming a closed-loop solution covering the entire process of "packaging - packing - sealing - re-inspection - palletizing". This further enhances the production automation level and overall efficiency, and is widely applicable to large-scale production scenarios in industries such as food, medicine, and cosmetics, achieving seamless connection from raw materials to storage of the products.

Integrated core advantages of the entire line

Full-process unmanned operation: From product packaging to palletizing and storage, no manual intervention is required. Only operators need to monitor the equipment operation status through the human-machine interface, reducing labor costs and human operational errors. For example, in the pharmaceutical industry, full-process unmanned operation can prevent direct contact between personnel and drugs, reducing the risk of drug contamination, and meeting the GMP standards of the pharmaceutical industry.

Comprehensive quality traceability system: The entire production line is equipped with a data collection system that can record real-time information such as the operating parameters of each equipment, the quantity and weight of product packaging, and weight detection data, and store it in the database. If quality issues are discovered later, the traceability system can be used to quickly query the production time, equipment number, operator, etc. of the product, facilitating problem investigation and responsibility determination. For example, if there is a problem with the weight of a certain batch of products in the food industry, the traceability system can be used to locate the detection data of the weighing machine and analyze whether it is due to a malfunction of the filling system or the packing machine.

Space utilization optimization: The palletizing equipment adopts a three-dimensional stacking method. Compared to manual stacking, it can increase the stacking height of cartons to 2-3 meters, significantly improving the utilization rate of storage space. At the same time, the layout of the entire line of equipment is compact. By reasonably planning the conveying path, the floor area occupied by the equipment is reduced, making it suitable for enterprises with limited production sites. For example, after a certain cosmetics company introduced this entire line of equipment into its original production workshop, the utilization rate of storage space increased by 40%, and it was able to meet production needs without the need for additional factory expansion.

Enhanced adaptability across multiple industries: All newly added equipment are equipped with flexible adjustment functions. They can adjust equipment parameters and operation modes according to the product characteristics and packaging requirements of different industries. For example, in the pesticide industry, for pesticide products with strong corrosiveness, the parts in contact with the equipment are made of corrosion-resistant stainless steel, and the sealing machine uses anti-corrosion tape to ensure the normal operation of the equipment; in the industrial component industry, the palletizing equipment can adjust the grasping force of the mechanical arm according to the weight of the component cartons to avoid damage to the cartons.