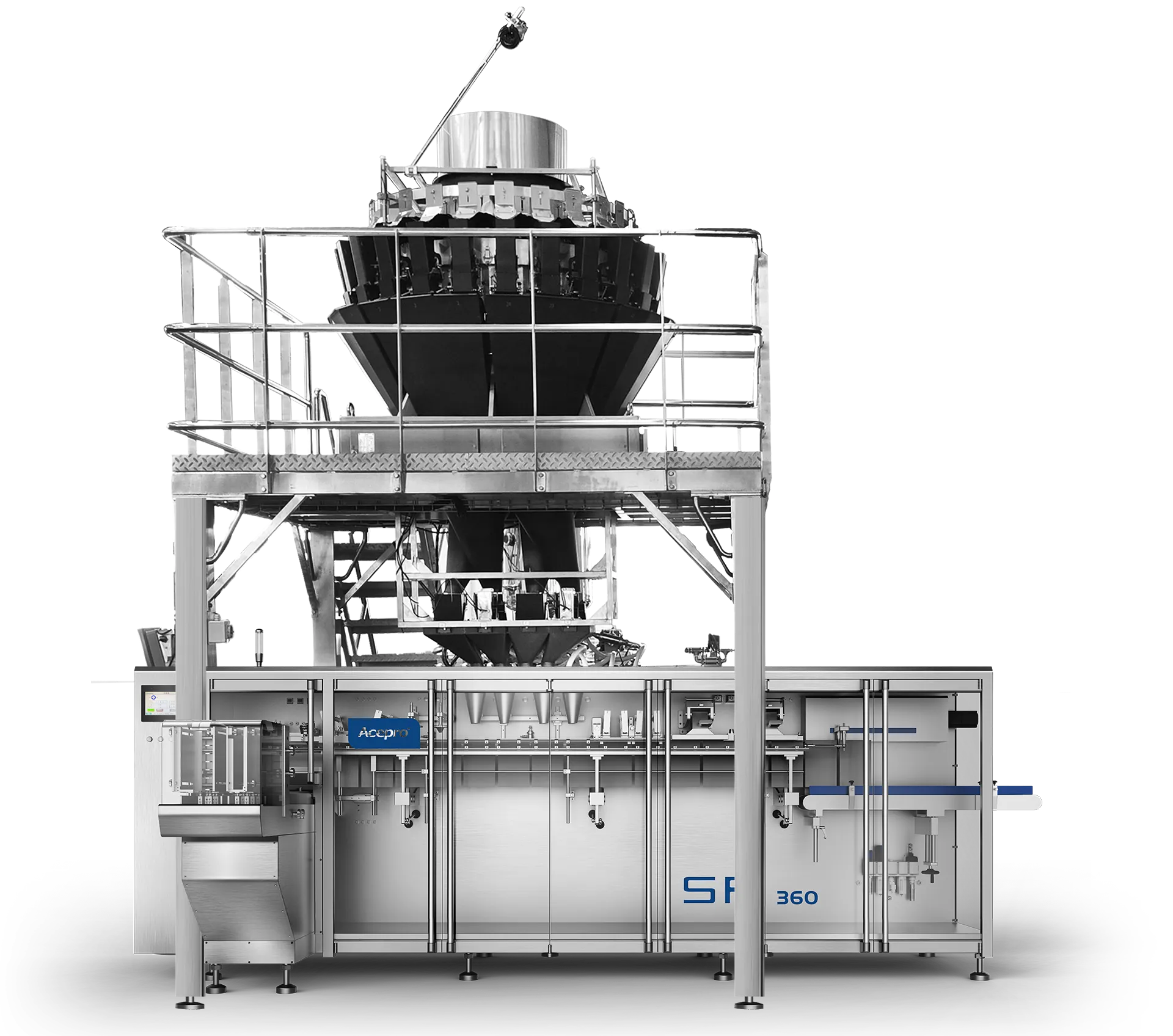

SP: Full-Servo Premade Bag Packaging Machine

Full servo Premade Pouch packaging machine. This machine features all core motion axes (from bag extraction, transmission, bag opening, filling to sealing) using servo motors as the driving and actuating components for an automated packaging system.

The servo bag supply

device operates

smoothly with high

control accuracy.

Four feeding devices,

with highfiling

accuracy and double

the speed.

Full servo structure,

more simple and stable,

with lower noise

Ultra-flexible, rapid production changeover (core value)

All motion parameters (travel, speed, acceleration, position) are digitized and stored in the recipe. When changing products, the operator only needs to click one button on the touch screen to call the new recipe. All servo axes automatically adjust to the new position without the need for any tools or manual mechanical adjustments. The production changeover time is shortened from several hours to just a few minutes or even seconds, perfectly adapting to the market trend of multiple varieties and small batches.

Ultra-high precision and reliability

The servo motor has extremely high positioning accuracy (up to ±0.1mm). This ensures that the success rates of bag taking, bag opening, and sealing are infinitely close to 100%, significantly reducing the failure rates of bag jams, bag drops, and poor packaging, minimizing material waste, and enhancing the overall efficiency of the equipment (OEE).

Runs smoothly and efficiently, with faster speed

The servo motor can optimize the motion curve (such as S-shaped acceleration and deceleration), making the start-up and movement process very smooth, eliminating the shock and vibration of the pneumatic mechanism. This allows the equipment to operate stably at higher speeds, while reducing noise, wear and tear, and extending the lifespan.

Energy conservation and environmental protection

Servo motors consume almost no power when stationary, while traditional pneumatic equipment requires the continuous operation of an air compressor, resulting in huge energy consumption. The comprehensive energy consumption of fully servo equipment can be reduced by 30% to 50%.

The foundation of digitization and intelligence

The fully servo architecture is inherently suitable for digitization. All motion data can be collected, monitored and analyzed, providing a solid data foundation for achieving predictive maintenance, quality traceability, integration with MES/ERP systems, and future artificial intelligence optimization.

Servo bag supply device

Combining a precise mechanical structure with multi-axis servo control, it operates stably, does not require manual adjustment of the machinery by humans, has a high degree of intelligence and high efficiency.

Dual-output mode

Each workstation adopts a dual-structure design, maximizing production efficiency, optimizing production layout, and enhancing return on investment (ROI)

Industries

Granular

Liquid

Powdery

Mixed