The Acepack SP-360D is a fully servo-driven preformed bag packaging machine that can produce various bagged and small-bag products from preformed bags to finished bags. These machines complete the opening of the packaging bag, product filling, and sealing during the horizontal movement, and are suitable for a variety of products such as food, medicine, and personal care products.

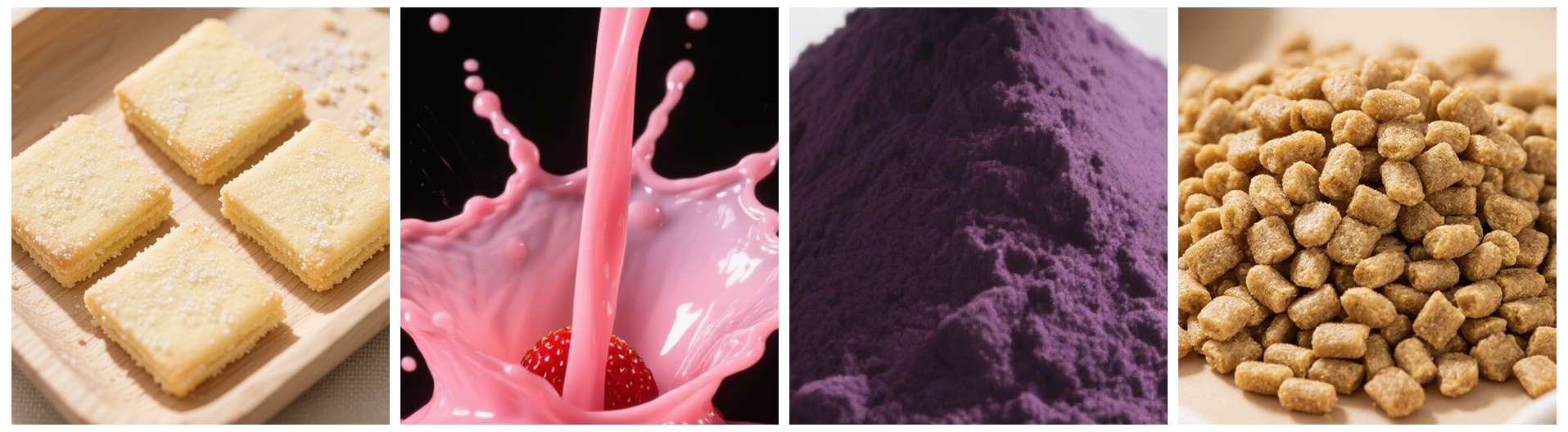

They can produce various types of bags, including blow-molded bags, self-standing bags, flat bags, and zipper bags, and can handle different types of products (liquids, powders, granules, solids).

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Main standard features

The machine adopts a fully servo-driven structure. All movements are precisely controlled by digital servo motors, completely replacing the traditional mechanical transmission. This not only simplifies the mechanical complexity but also brings advantages such as extremely smooth operation, extremely high control accuracy, and significant reduction in overall noise. Combined with a high-performance servo bag supply device, it realizes smooth, precise and efficient processes of bag extraction, bag opening and bag delivery, laying a solid foundation for high-speed production.

The machine with the latest generation intelligent control system, it is the "smart brain" of the equipment. This system optimizes the motion control algorithm through deep optimization and realizes real-time data interaction, thereby maximizing the overall efficiency (OEE) of the equipment. It can effectively reduce micro-stops, compress production changeover time, ensure operating speed, and comprehensively empower from three dimensions: availability rate, performance rate, and defect rate, achieving a leap in production capacity and efficiency.

Life cycle intelligent management: The equipment possesses advanced self-monitoring and data analysis capabilities. It can continuously track the operating duration, load, and status of key components, enabling predictive maintenance. It can proactively alert before potential failures occur and scientifically plan maintenance schedules, maximizing equipment availability and service life.

Real-time safety monitoring: A built-in highly sensitive operation mechanism monitoring system is incorporated. It can promptly detect any abnormal vibrations, displacements, or overloads during the equipment's operation and immediately implement protective shutdowns, providing comprehensive and proactive safety protection for the equipment and operators.

The highly integrated automated and intelligent design has brought about a revolutionary and user-friendly operation experience. The intuitive graphical human-machine interface (HMI) and automated recipe management have greatly reduced the requirements for the professional skills and experience of operators, effectively minimizing human operational errors, and significantly saving training and labor costs.

The machine with the latest generation intelligent control system, it is the "smart brain" of the equipment. This system optimizes the motion control algorithm through deep optimization and realizes real-time data interaction, thereby maximizing the overall efficiency (OEE) of the equipment. It can effectively reduce micro-stops, compress production changeover time, ensure operating speed, and comprehensively empower from three dimensions: availability rate, performance rate, and defect rate, achieving a leap in production capacity and efficiency.

Life cycle intelligent management: The equipment possesses advanced self-monitoring and data analysis capabilities. It can continuously track the operating duration, load, and status of key components, enabling predictive maintenance. It can proactively alert before potential failures occur and scientifically plan maintenance schedules, maximizing equipment availability and service life.

Real-time safety monitoring: A built-in highly sensitive operation mechanism monitoring system is incorporated. It can promptly detect any abnormal vibrations, displacements, or overloads during the equipment's operation and immediately implement protective shutdowns, providing comprehensive and proactive safety protection for the equipment and operators.

The highly integrated automated and intelligent design has brought about a revolutionary and user-friendly operation experience. The intuitive graphical human-machine interface (HMI) and automated recipe management have greatly reduced the requirements for the professional skills and experience of operators, effectively minimizing human operational errors, and significantly saving training and labor costs.

Packaging formats

Technical specifications

| Model | SP-240 | SP-360D | SP-480Q | SP-480D |

|---|---|---|---|---|

| Pouch Size | 90*110 (Min) 240*350 (Max) |

90*110 (Min) 180*310 (Max) |

60*80 (Min) 120*225 (Max) |

90*110 (Min) 240*350 (Max) |

| Maximum capacity | 2500ml | 1200ml | 180ml | 2500ml |

| Packaging Capacity | 50-70ppm | 100-140ppm | 200-260ppm | 100-130ppm |

| Energy Consumption | 11.5kw/h | 8.5kw/h | 9kw/h | 9kw/h |

| Air Consumption | 180NL/min | 200NL/min | 220NL/min | 200NL/min |

| Machine Dimensions | 3800*2350*1700 (L*W*H) |

5050*2450*1700 (L*W*H) |

6500*1240*1500 (L*W*H) |

5900*1240*1500 (L*W*H) |

| Weight | 3500kg | 4500kg | 6080kg | 6100kg |

Application

A wide range of dosing systems for all types of products on the market