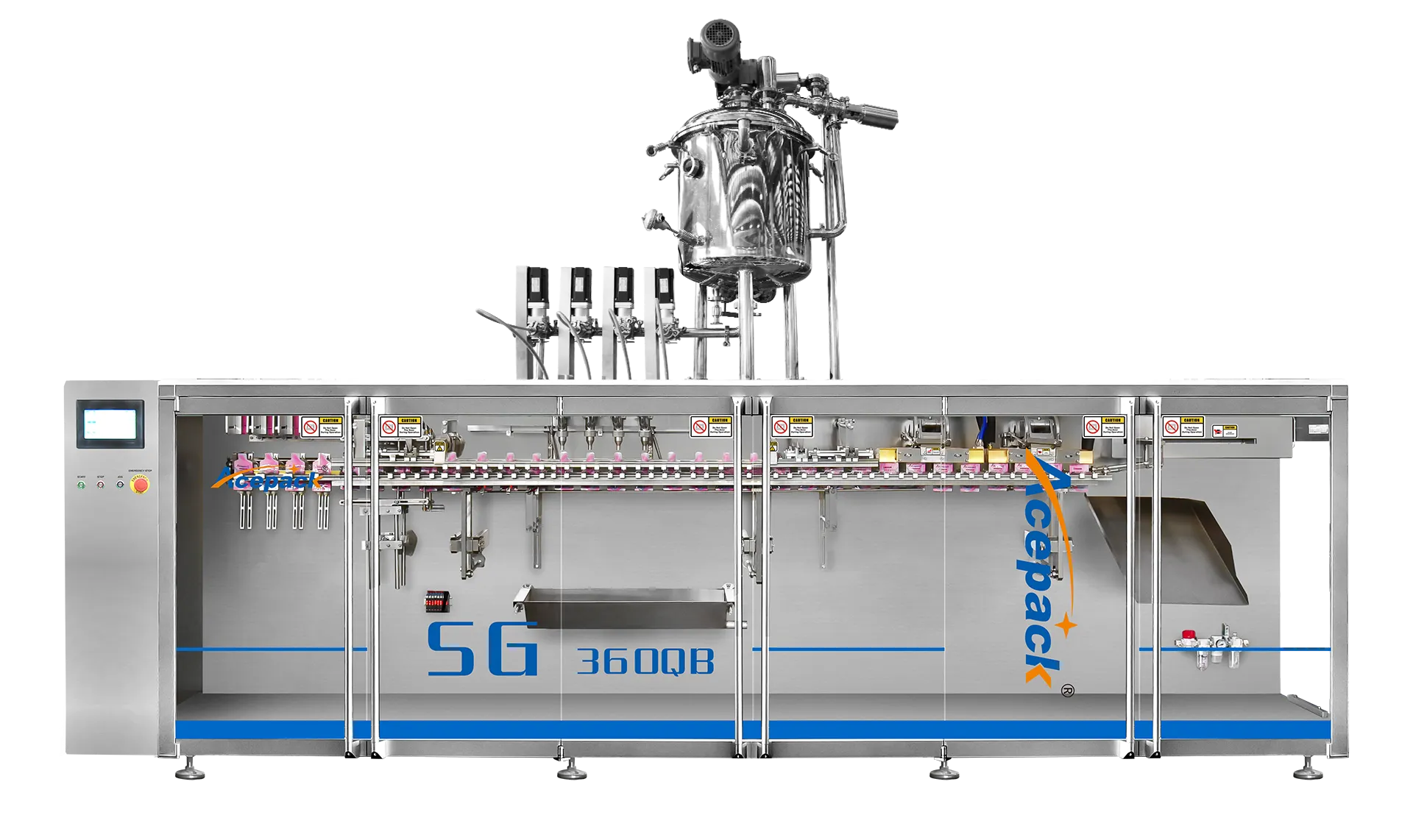

SG:Premade Pouch Packing Machine

ACEPACK premade pouch filling machines are specifically engineered to fill and seal various materials into premade pouches. These machines are fully automated and controlled. These machines are widely used across the food, beverage, cosmetics, chemical, and pharmaceutical industries.

Four-out mode, 240

packs per minute

4 anti-drip filling heads,

with high filling accuracy

Mechanical bag stretching

device, which can flatten the

bags after filling.

One group has hot sealing, the

other group has cold sealing. The

packaging edges produced are

smooth, without wrinkles or cured

1.Pouch Feeding Conveyor;

2.Flip-Out Pouch-Picking Unit;

3.Independent blowing station:Nitrogen can be blown to extend the shelf life;Bagless detection can be added to avoid material wasteand reduce equipment pollution

4.Duplex Filling Stations:the filling time and increase the packaging speed;Can cast desiocant, can fill mixed material

5.Duplex Top Sealing:Increase the cold seal to ensure the firmness and aesthelicsof the seal

The machine comprises three key components: a pouch feeding conveyor, a pick-and-place unit for transferring pouches, and a main module for opening, filling, and top sealing. It comes equipped with an independent electrical cabinet and the control system.Available optional equipment includes a coders, hole punchers, notchers, cap fitments etc. we are able to install multihead weighers.

ACEPACK premade pouch filling machines are supporting multiple pouch styles such as stand-up, zipper, spout, and quad-seal zipper pouches. They are capable of handling liquids, pastes, solids, and other products, using laminated films like PE/NY/AL/PET/CPP."

Pouch Feeding System

Pouch feeding systems are designed to automatically handle pre-made bags, reducing the need for manual intervention and improving operational efficiency.

Pouch feeding systems are adjustable or customizable to accommodate different bag sizes and shapes, providing manufacturers with versatility.

Pick-and-place systems are used to feed bags into filling stations.

Dual-filling System

The dual-filling system significantly enhances operational efficiency through its innovative design. It ensures high-precision filling operations while enabling the simultaneous handling of two distinct products. This integrated approach optimizes the filling process for various industrial applications.

Pouch Stretching Station

Ensure the bag is sealed properly without wrinkles or folds, which contributes to a professional appearance

Servo WB structure

Servo WB Structure is a sophisticated and highly efficient conveyance system within premade pouch packing machines. By combining the precise, step-by-step motion of a walking beam with the advanced control of servo motors, this structure ensures accurate positioning, high-speed operation, and the flexibility required in modern packaging environments

Industries

Granular

Liquid

Powdery

Mixed