The most intelligent and competitive packaging solution provided by the manufacturer

Acepack SF-360D is a fully servo-driven film packaging machine that can produce various bagged and small-bagged products from the roll film to the finished bags. These machines complete the forming, product filling and sealing of the packaging bags during horizontal movement, and are suitable for a variety of products such as food, medicine and personal care products.

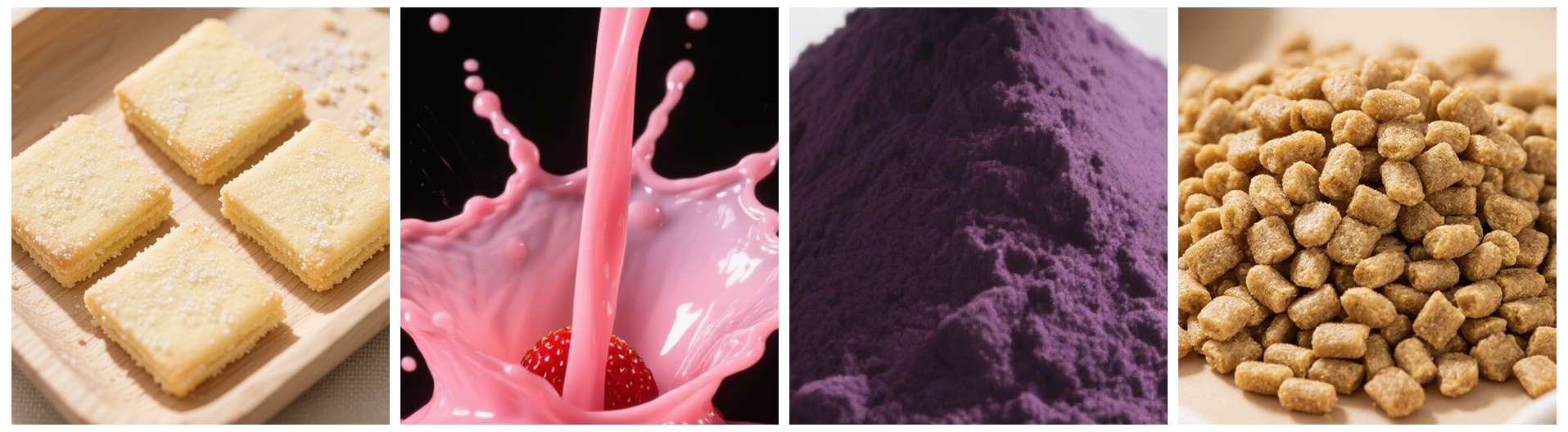

They can produce various types of bags, including suction bag, self-standing bag, flat bag and zipper bag, and can handle different types of products (liquids, powders, granules, solids).

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Main standard features

The fully automated packaging machine integrates the concepts of Industry 4.0, aiming to create an intelligent and highly efficient packaging solution:

Intelligent data management and one-click production changeover:

The machine is equipped with a new generation control system, featuring powerful data interconnection capabilities. You can easily retrieve and analyze historical production data and process formulas, providing precise support for optimizing production. Through the one-click production changeover technology, simply select the formula and the equipment can automatically complete all precise adjustments to parameters and mechanisms, minimizing the changeover time and human error, making it a key tool for enhancing the comprehensive efficiency of OEE equipment.

Full servo drive and outstanding performance:

By adopting a full servo motor drive structure and eliminating complex mechanical transmissions, this approach not only simplifies the mechanical design but also provides a superior experience with extremely smooth operation, significantly reduced noise, and decreased maintenance requirements. It also achieves higher operational stability and longer equipment lifespan.

Comprehensive security monitoring and precise sealing:

Intelligent safety protection: It features real-time monitoring of the operation mechanism, enabling the real-time detection of equipment status. It promptly issues warnings for abnormal situations and takes protective measures, significantly enhancing the safety and reliability of equipment operation.

Perfect sealing quality: The sealing process employs advanced servo-following positioning technology to ensure that the sealing knife maintains precise synchronization with the packaging material during the dynamic process. This significantly reduces the allowable sealing error and eliminates misalignment, making the packaging seal more flat, beautiful, and enhancing the product's grade.

Intelligent Cost Reduction and Efficiency Enhancement:

The highly integrated automation and intelligence design makes the equipment operation intuitive and simple, significantly reducing the requirements for the operators' experience and skills, effectively lowering the labor costs and training costs, and making your production management more effortless and efficient.

Intelligent data management and one-click production changeover:

The machine is equipped with a new generation control system, featuring powerful data interconnection capabilities. You can easily retrieve and analyze historical production data and process formulas, providing precise support for optimizing production. Through the one-click production changeover technology, simply select the formula and the equipment can automatically complete all precise adjustments to parameters and mechanisms, minimizing the changeover time and human error, making it a key tool for enhancing the comprehensive efficiency of OEE equipment.

Full servo drive and outstanding performance:

By adopting a full servo motor drive structure and eliminating complex mechanical transmissions, this approach not only simplifies the mechanical design but also provides a superior experience with extremely smooth operation, significantly reduced noise, and decreased maintenance requirements. It also achieves higher operational stability and longer equipment lifespan.

Comprehensive security monitoring and precise sealing:

Intelligent safety protection: It features real-time monitoring of the operation mechanism, enabling the real-time detection of equipment status. It promptly issues warnings for abnormal situations and takes protective measures, significantly enhancing the safety and reliability of equipment operation.

Perfect sealing quality: The sealing process employs advanced servo-following positioning technology to ensure that the sealing knife maintains precise synchronization with the packaging material during the dynamic process. This significantly reduces the allowable sealing error and eliminates misalignment, making the packaging seal more flat, beautiful, and enhancing the product's grade.

Intelligent Cost Reduction and Efficiency Enhancement:

The highly integrated automation and intelligence design makes the equipment operation intuitive and simple, significantly reducing the requirements for the operators' experience and skills, effectively lowering the labor costs and training costs, and making your production management more effortless and efficient.

Packaging formats

Technical specifications

| Model | SF-480D | SF-360D | SF-480Q | SF-240 | SF-240D | SF-180 |

|---|---|---|---|---|---|---|

| Pouch Size | 90*110 (Min) 240*350 (Max) |

80*110 (Min) 180*270 (Max) |

60*80 (Min) 120*225 (Max) |

90*110 (Min) 240*350 (Max) |

60*80 (Min) 120*225 (Max) |

90*110 (Min) 180*260 (Max) |

| Maximum capacity | 2500ml | 1200ml | 180ml | 2500ml | 180ml | 1200ml |

| Packaging Capacity | 100-140ppm | 100-140ppm | 200-260ppm | 50-70ppm | 100-140ppm | 50-70ppm |

| Energy Consumption | 16kw/h | 17kw/h | 18kw/h | 16kw/h | 17kw/h | 15kw/h |

| Air Consumption | 300NL/min | 300NL/min | 400NL/min | 300NL/min | 300NL/min | 300NL/min |

| Machine Dimensions | 13200*1580*1850 (L*W*H) |

11000*1700*1850 (L*W*H) |

12800*1240*1500 (L*W*H) |

9000*1500*1850 (L*W*H) |

9500*1500*1850 (L*W*H) |

7650*1500*1850 (L*W*H) |

| Weight | 8300kg | 8000kg | 10800kg | 6600kg | 6900kg | 5600kg |

Application

A wide range of dosing systems for all types of products on the market