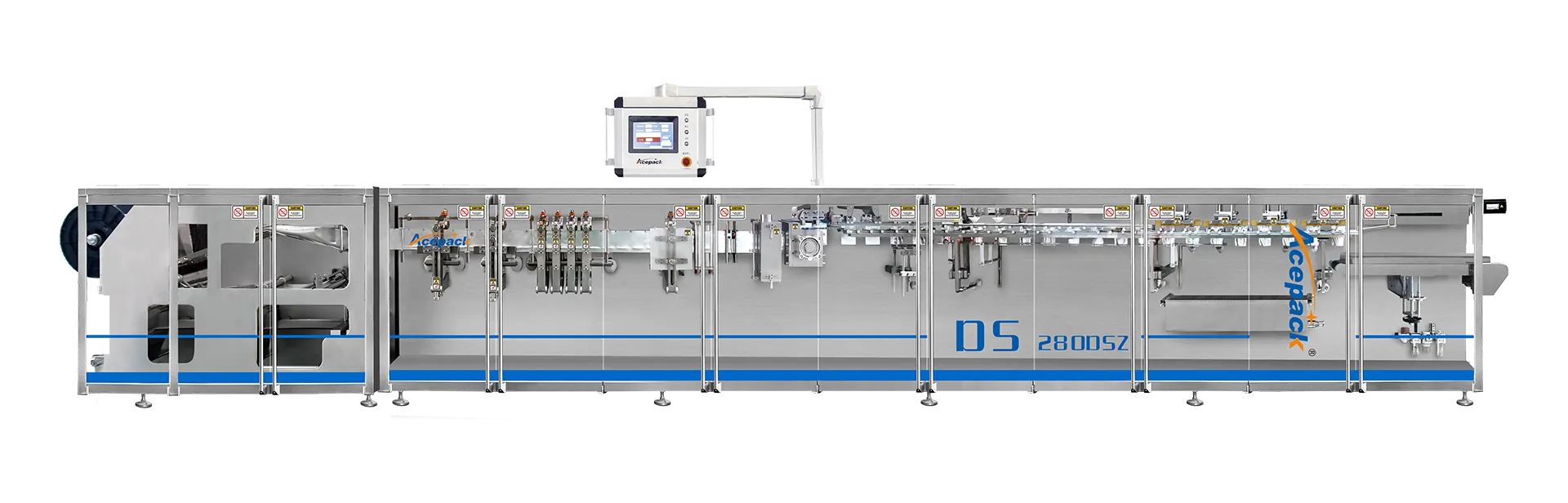

DS: Doypack Packing Machine

The roll film self-standing bag packaging machine is a representative of technology-intensive products in the field of flexible packaging. It integrates materials science, mechanical engineering, servo control and automation technology perfectly, providing users with a one-stop solution from roll film to finished packaging.

Zipper mechanism,

capable of synchronizing

the equipment

The servo bagging

device operates stably

and with precise travel.

Customizable cut

pouch shape

It can be matched with4

flling heads and can

perform two separate

feedings, resulting in a

speed increase of 1 times.

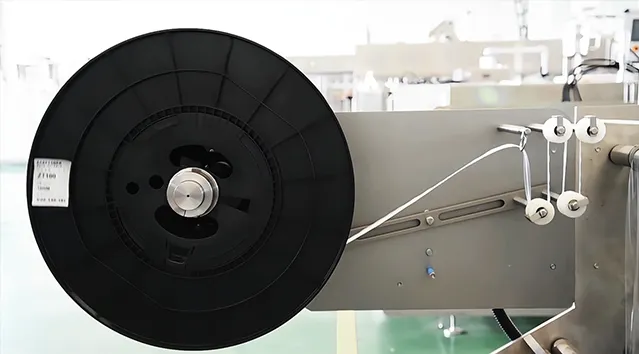

Spindle,flm feeding, bag

pulling, and the WB all

equipped with servo motors.

High efficiency: Continuous production, with a speed of up to several dozen to hundreds of packages per minute.

Low cost: The cost of the roll film is lower than that of the prefabricated bags, resulting in high overall cost-effectiveness.

High quality: Integrated production, reducing pollution risks; excellent sealing quality, long shelf life.

High visibility: Self-sealing bags are one of the most popular packaging forms on the market.

Flexibility: Capable of handling small batches and a variety of products in orders.

Application fields:

Food industry: Potato chips, nuts, coffee, sauces, pet food, frozen food, milk powder, etc.

Cosmetics industry: Laundry detergents, shampoos, skin care products, etc.

Health supplement industry: Pulp, beverages, etc.

Zipper device

The self-standing bag packaging machine can be equipped with a zipper device. The formed roll film can be embedded into the packaging bag, and the zipper edge sealing is both beautiful and sturdy.

Adding suction nozzle device

An additional suction nozzle device can be added. It can be customized based on the size and shape of the suction nozzle. The vibration plate, guide rail, and mechanical clamps can all be customized, resulting in a high degree of customization.

Industries

Granular

Liquid

Powdery

Mixed