The S-180DB is a model specifically designed for irregular flat bags. It offers a visually appealing packaging effect and allows for customization of the bag shape. The equipment has high filling accuracy.

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Main standard features

Intelligent servo bagging system

Equipped with a fully digital control system, all parameters (bag length, speed, tension, etc.) are integrated on a touch screen. This significantly reduces operational difficulty and production changeover time, perfectly meeting the requirements of flexible production.

It uses high-response servo motors for direct drive, combined with advanced motion control algorithms, to achieve precise control of film traction in milliseconds. It completely eliminates the gaps, inertia, and crawling phenomena in traditional mechanical transmission, with the traction length accuracy reaching within ±0.5mm, ensuring consistency of each batch of products and significantly reducing material waste.

The power system uses large-torque servo motors, with smooth startup and braking, and can provide abundant power even when tractioning thick films at high speeds, preventing slipping. The strong power reserve enables the equipment to operate at high speed continuously.

Servo WB

The cart is equipped with precise linear guides and gear rack transmission, featuring an extremely low friction coefficient and smooth operation. It enables the cart to achieve extremely high acceleration and deceleration during high-speed reciprocating motion, significantly shortening the working cycle and being a key component for enhancing the overall efficiency of the machine.

The core guide rails and sliders are made of high-quality aluminum alloy and undergo hardening treatment, ensuring wear resistance and corrosion resistance. The entire transmission system operates in a sealed environment, effectively preventing dust and debris, overcoming the shortcomings of traditional sliding rails that are prone to wear and require frequent maintenance. The average trouble-free operating time (MTBF) is greatly extended, effectively reducing long-term maintenance costs.

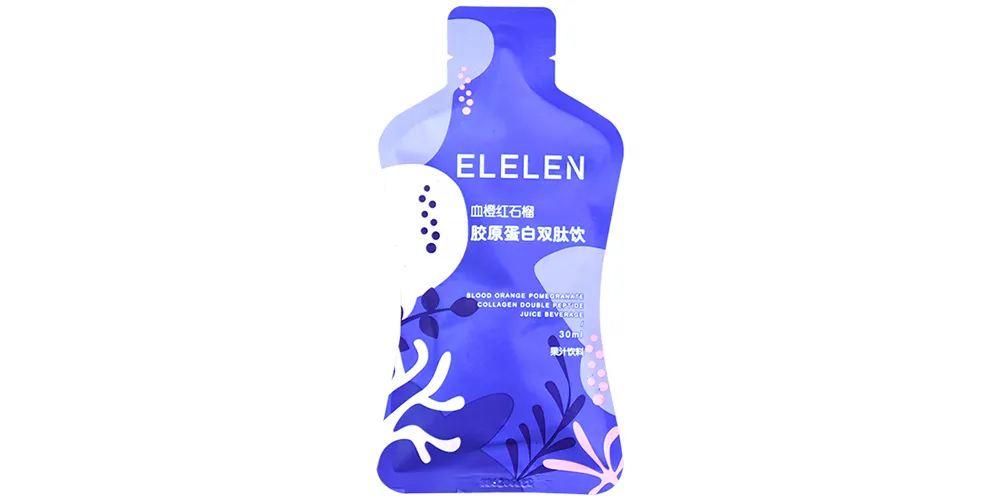

Customizable bag shapes

We offer modular molds and actuator designs, allowing you to flexibly customize various special-shaped bags according to your brand requirements. By simply replacing a few components, you can achieve this. This helps you break free from the constraints of traditional bag shapes, seize the market opportunity with unique packaging designs, and enhance brand recognition.

Efficient dual-output mode

The innovative dual-channel parallel operation design is like having two independent and synchronized production lines integrated within one device. From sealing and filling to output, all processes are carried out in parallel on two lines.

You don't need to purchase two devices, occupy twice the space and consume twice the energy. You can achieve double the output, significantly reducing the production cost per package, and it is the optimal solution for handling large orders and increasing the return on investment.

Equipped with a fully digital control system, all parameters (bag length, speed, tension, etc.) are integrated on a touch screen. This significantly reduces operational difficulty and production changeover time, perfectly meeting the requirements of flexible production.

It uses high-response servo motors for direct drive, combined with advanced motion control algorithms, to achieve precise control of film traction in milliseconds. It completely eliminates the gaps, inertia, and crawling phenomena in traditional mechanical transmission, with the traction length accuracy reaching within ±0.5mm, ensuring consistency of each batch of products and significantly reducing material waste.

The power system uses large-torque servo motors, with smooth startup and braking, and can provide abundant power even when tractioning thick films at high speeds, preventing slipping. The strong power reserve enables the equipment to operate at high speed continuously.

Servo WB

The cart is equipped with precise linear guides and gear rack transmission, featuring an extremely low friction coefficient and smooth operation. It enables the cart to achieve extremely high acceleration and deceleration during high-speed reciprocating motion, significantly shortening the working cycle and being a key component for enhancing the overall efficiency of the machine.

The core guide rails and sliders are made of high-quality aluminum alloy and undergo hardening treatment, ensuring wear resistance and corrosion resistance. The entire transmission system operates in a sealed environment, effectively preventing dust and debris, overcoming the shortcomings of traditional sliding rails that are prone to wear and require frequent maintenance. The average trouble-free operating time (MTBF) is greatly extended, effectively reducing long-term maintenance costs.

Customizable bag shapes

We offer modular molds and actuator designs, allowing you to flexibly customize various special-shaped bags according to your brand requirements. By simply replacing a few components, you can achieve this. This helps you break free from the constraints of traditional bag shapes, seize the market opportunity with unique packaging designs, and enhance brand recognition.

Efficient dual-output mode

The innovative dual-channel parallel operation design is like having two independent and synchronized production lines integrated within one device. From sealing and filling to output, all processes are carried out in parallel on two lines.

You don't need to purchase two devices, occupy twice the space and consume twice the energy. You can achieve double the output, significantly reducing the production cost per package, and it is the optimal solution for handling large orders and increasing the return on investment.

Packaging formats

Technical specifications

| Technical parameter | S-130B | S-180DB |

| Pouch Size(mm) | 50X80(Min.) 130X225(Max.) |

60X120(Min.) 85X225(Max.) |

| Filling Capacity | 220ml | 80ml |

| Packaging Speed | 40–60ppm | 80–120ppm |

| Power | 5.9kw | 6.8kw |

| Air Consumption | 300NL/min | 450NL/min |

| Machine Dimensions(mm) | 3065(L)970(W)1500(H) | 5630(L)970(W)1500(H) |

| Weight | 1000kg | 1600kg |

Application

A wide range of dosing systems for all types of products on the market

How It Work?