The most intelligent and competitive packaging solutions provided by the manufacturer

The Acepack IP-210 flexible horizontal packaging machine is a type of flexible packaging machine that can produce various bagged and small-bagged packages from pre-made bags. These machines complete the forming, product filling and sealing of the packaging bags during horizontal movement, making them suitable for a wide range of products such as food, medicine and personal care products.

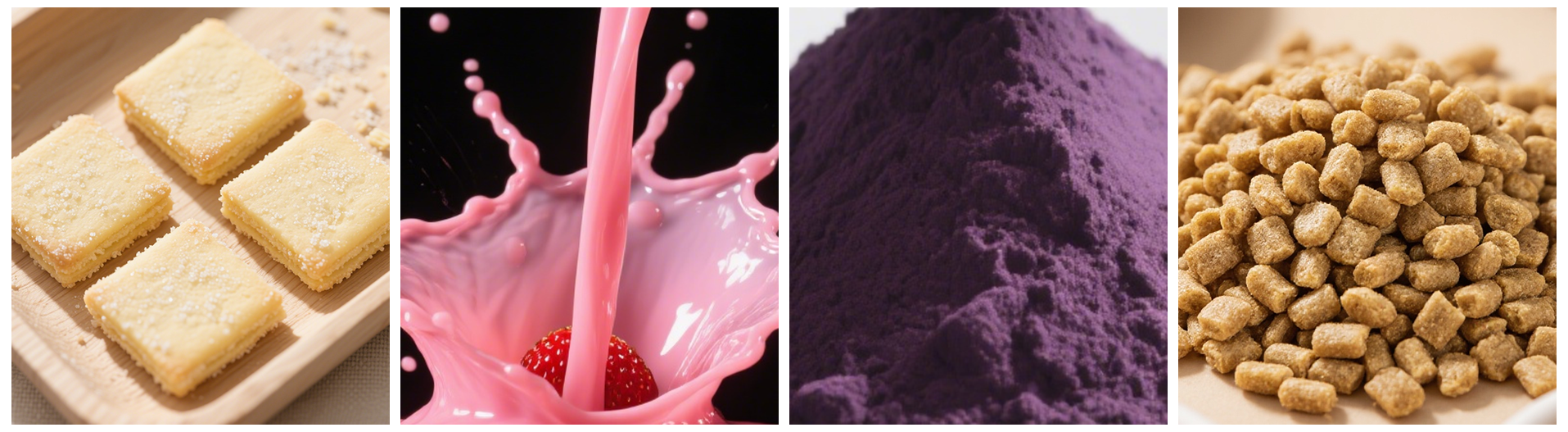

They can produce various types of bags, including M bags, self-standing bags, flat bags and zipper bags, and can handle different product types (liquids, powders, granules, solids).

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Main standard features

One-click production changeover

This is not just a button, but a complete intelligent system. The operator only needs to select the model of the product to be produced (such as "Product A") on the touch screen and press the "Changeover" button. The packaging machine will automatically complete all the switching actions.

Automatic parameter adjustment: The servo motor automatically drives all the adjustment mechanisms (such as the width of the material rack, bag length, gripper position, discharge height, etc.) to the preset precise positions, eliminating the need for manual measurement and adjustment.

Automatic recipe invocation: The system automatically retrieves all the parameters (such as temperature, pressure, speed, torque, etc.) corresponding to the product from the cloud or local database.

Life cycle management

This is a predictive maintenance function based on the Industrial Internet of Things. The system continuously monitors the operating status of key components (such as servo motors, bearings, seals, and knives) through sensors (such as temperature, vibration, current, and operating cycles, etc.).

Health monitoring: Real-time display of the life percentage of core components.

Predictive alarm: Before the component completely fails, the system will give an early warning (such as "The remaining life of XX bearing is estimated to be 500 hours"), prompting planned maintenance.

Data traceability: Record all events, alarms, production data, and maintenance records of the packaging machine throughout its entire life cycle, forming a complete digital twin archive.

OEE Efficiency Improvement

The equipment is equipped with an OEE calculator built-in, which automatically and in real-time monitors and analyzes the three core elements that affect the overall equipment efficiency: Availability: Automatically record downtime and reasons (such as changeover, malfunction, waiting for materials)

Performance rate: Monitor the gap between the actual production speed and the theoretical maximum speed, and record the micro-stoppage losses.

Yield rate: Automatically count the number of defective and substandard products through visual inspection or sensors.

Compatibility with a wide range of sizes

This demonstrates the ultimate flexibility of the equipment. Through full servo drive and modular design, a single machine can cover an extremely wide range of product sizes without the need to replace a large number of parts.

"Multi-purpose in one machine": Meeting the demand for future product line expansion, customers do not need to repeatedly invest in new equipment due to size changes.

Protecting investment: The capacity of a single device can cover the production capacity of multiple old production lines, greatly improving the return on investment and site utilization rate.

Quick response to the market: It can quickly accept orders of various specifications and seize market opportunities.

4.0 Human-Machine Interface

This is far more than just a touchscreen. It is an intelligent terminal integrating operation, diagnosis, analysis, and remote collaboration.

Multi-level permission management: Different access permissions are set for operators, maintenance engineers, and administrators to ensure security.

Remote access: Supports secure VPN connection, allowing equipment manufacturer experts to remotely diagnose, debug, and update programs, achieving "zero-distance" service and reducing downtime.

Data cockpit: Key data (OEE, output, status, energy consumption) are centrally displayed in a dashboard format for easy understanding.

This is not just a button, but a complete intelligent system. The operator only needs to select the model of the product to be produced (such as "Product A") on the touch screen and press the "Changeover" button. The packaging machine will automatically complete all the switching actions.

Automatic parameter adjustment: The servo motor automatically drives all the adjustment mechanisms (such as the width of the material rack, bag length, gripper position, discharge height, etc.) to the preset precise positions, eliminating the need for manual measurement and adjustment.

Automatic recipe invocation: The system automatically retrieves all the parameters (such as temperature, pressure, speed, torque, etc.) corresponding to the product from the cloud or local database.

Life cycle management

This is a predictive maintenance function based on the Industrial Internet of Things. The system continuously monitors the operating status of key components (such as servo motors, bearings, seals, and knives) through sensors (such as temperature, vibration, current, and operating cycles, etc.).

Health monitoring: Real-time display of the life percentage of core components.

Predictive alarm: Before the component completely fails, the system will give an early warning (such as "The remaining life of XX bearing is estimated to be 500 hours"), prompting planned maintenance.

Data traceability: Record all events, alarms, production data, and maintenance records of the packaging machine throughout its entire life cycle, forming a complete digital twin archive.

OEE Efficiency Improvement

The equipment is equipped with an OEE calculator built-in, which automatically and in real-time monitors and analyzes the three core elements that affect the overall equipment efficiency: Availability: Automatically record downtime and reasons (such as changeover, malfunction, waiting for materials)

Performance rate: Monitor the gap between the actual production speed and the theoretical maximum speed, and record the micro-stoppage losses.

Yield rate: Automatically count the number of defective and substandard products through visual inspection or sensors.

Compatibility with a wide range of sizes

This demonstrates the ultimate flexibility of the equipment. Through full servo drive and modular design, a single machine can cover an extremely wide range of product sizes without the need to replace a large number of parts.

"Multi-purpose in one machine": Meeting the demand for future product line expansion, customers do not need to repeatedly invest in new equipment due to size changes.

Protecting investment: The capacity of a single device can cover the production capacity of multiple old production lines, greatly improving the return on investment and site utilization rate.

Quick response to the market: It can quickly accept orders of various specifications and seize market opportunities.

4.0 Human-Machine Interface

This is far more than just a touchscreen. It is an intelligent terminal integrating operation, diagnosis, analysis, and remote collaboration.

Multi-level permission management: Different access permissions are set for operators, maintenance engineers, and administrators to ensure security.

Remote access: Supports secure VPN connection, allowing equipment manufacturer experts to remotely diagnose, debug, and update programs, achieving "zero-distance" service and reducing downtime.

Data cockpit: Key data (OEE, output, status, energy consumption) are centrally displayed in a dashboard format for easy understanding.

Packaging formats

Technical specifications

| Pre-made Bag Machine | Model | IP210 | IP320C | IP430L |

| Bag Size (Width x Height x Bottom) (mm) | Minimum: 90 x 120 × (25 × 2) Maximum: 210 × 350 × (50 × 2) |

Minimum: 130×200×(25×2) Maximum: 320×600×(75×2) | Minimum: 170×300×(25×2) Maximum: 430×1000×(75×2) | |

| Packing Machine - Packing Speed | 80-120 bags/min | 60-150 bags/min | 10-50 bags/min | |

| Energy Consumption | ≈10KW/h | ≈16KW/h | ≈8KW/h | |

| Air Consumption | ≈1m³/min | ≈1m³/min | ≈1m³/min | |

| Equipment Weight (kg) | ≈8000kg | ≈10000kg | ≈10000kg | |

| Equipment Dimensions (Length × Width × Height) | 4800×1410×2150 | 7000×2200×2150 | 5300×2150×2750 |

Application

A wide range of dosing systems for all types of products on the market