A premade pouch packaging machine is a full automated piece of equipment that works with pouches that are already manufactured and ready for filling. This Premade pouch machines are engineered to handle a pouch styles including stand-up pouches (also known as Doypacks), flat pouches.

Main standard features

Increased Efficiency and Productivity: Some machines can process over 120 pouches per minutes.This automation allows for continuous operation and frees up employees for other tasks.

Automatic Bag Handling: Key features include automatic bag taking from a magazine, feeding the bag into the filling station, and precise opening of the pouch.Some machines include sensors to detect if a pouch is properly opened, preventing product spillage and waste.Defective rate as low as 0.5%

Precise Filling Systems: Depending on the product, these machines can be equipped with various fillers, such as auger fillers for powders, liquid pumps for liquids, and multi-head weighers for solids, ensuring accurate measurement.Packaging accuracy can reach ±0.5%

Advanced Sealing Technology: The machines utilize heat or ultrasonic tools to create a secure and consistent seal on the pouches.

Pouch Coding and Printing: Many machines can be integrated with printing equipment to add date codes, lot numbers, or other essential information to the packages.

User-Friendly Controls: Modern machines often feature intuitive touch screen control systems that are easy for operators to use.

Integration Capabilities: They are designed to be versatile and can be easily integrated with other packaging line equipment, such as checkweighers, metal detectors, and case sealers.

Packaging formats

Technical specifications

|

Model |

SG-180 |

SG-210 |

SG-240 |

SG-280 |

SG-360D |

|

Maximum Packing Volume |

1200ml |

1600ml |

2000ml |

3000ml |

1200ml |

|

Max Pouch Size |

180mm*310mm |

210mm*310mm |

240mm*350mm |

280mm*400mm |

180mm*310mm |

|

Min Pouch Size |

60mm*80mm |

90mm*110mm |

90mm*120mm |

90mm*120mm |

90mm*110mm |

|

Packing Speed |

30-60ppm |

30-60ppm |

30-60ppm |

30-60ppm |

60-120ppm |

|

Air Consumption |

200NL/min |

200NL/min |

400NL/min |

400NL/min |

500NL/min |

|

Input Power |

1.8kw |

2.8kw |

3.4kw |

5.5kw |

4.5kw |

|

Working Power Supply |

AC 380V 50Hz |

AC 380V 50Hz |

AC 380V 50Hz |

AC 380V 50Hz |

AC 380V 50Hz |

|

Equipment Weight |

700kg |

900kg |

1040kg |

1800kg |

2000kg |

|

L*W*H |

1990*970*1390mm |

2700*970*1400mm |

3100*1010*1400mm |

4100*1020*1500mm |

4055*980*1400mm |

Application

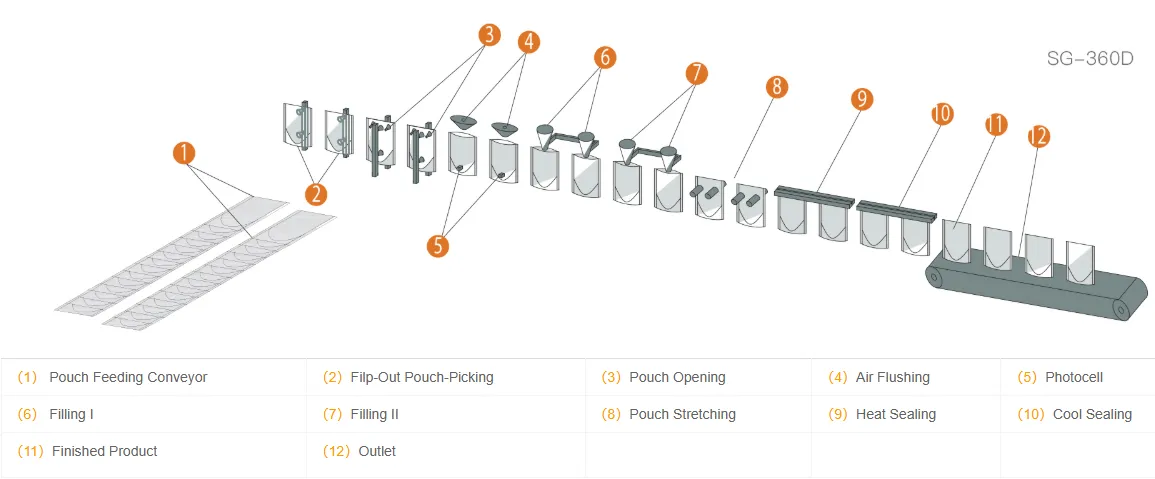

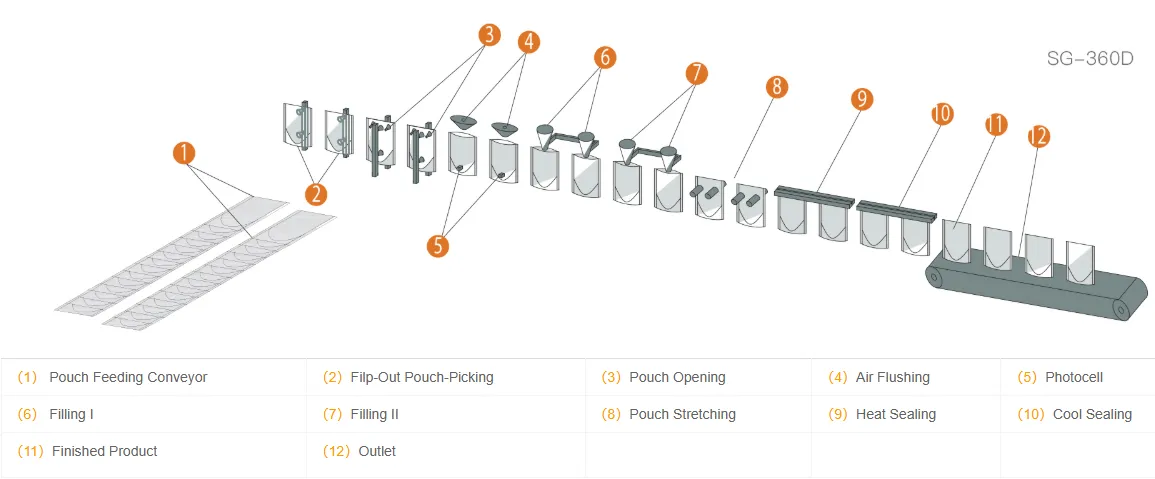

How It Work?

How It Work?