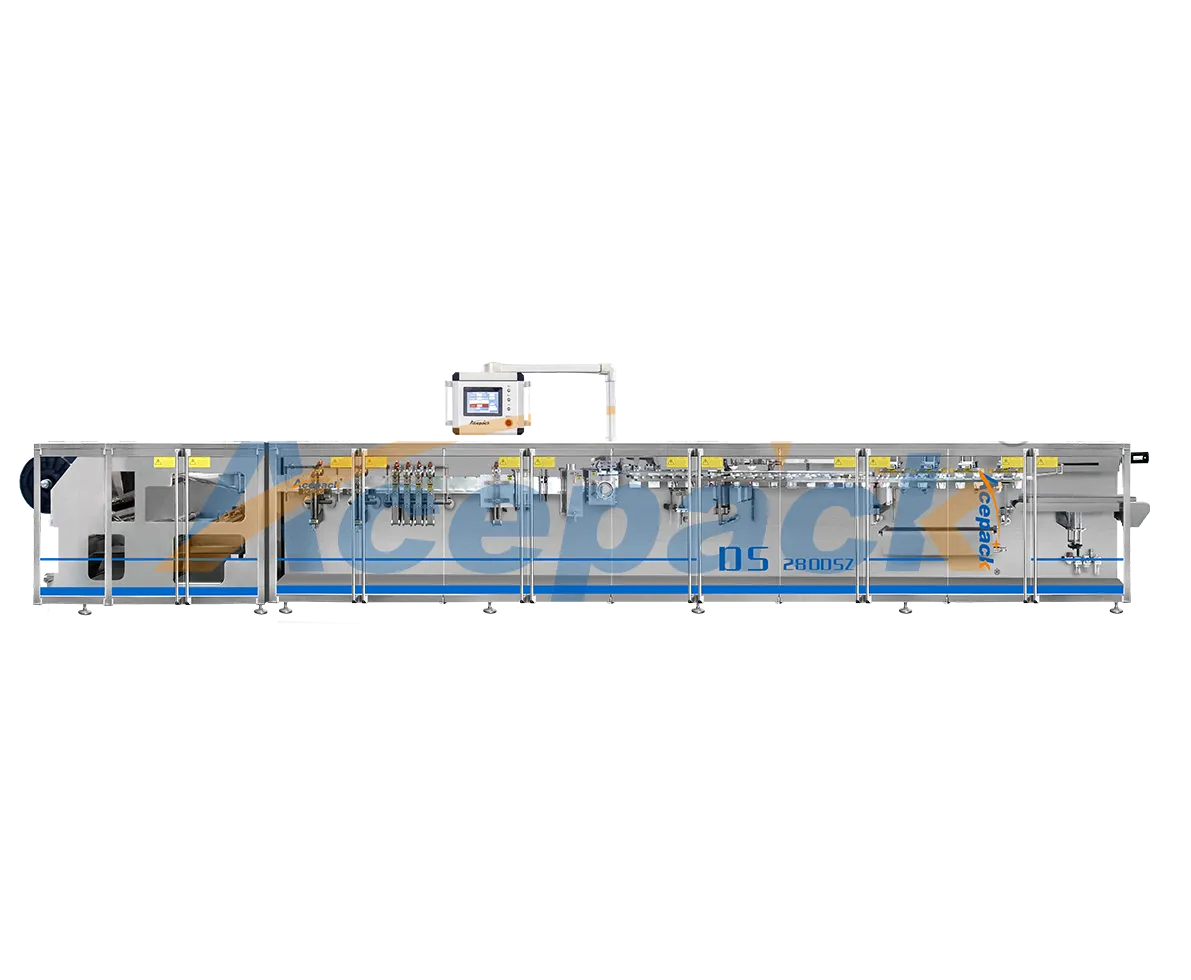

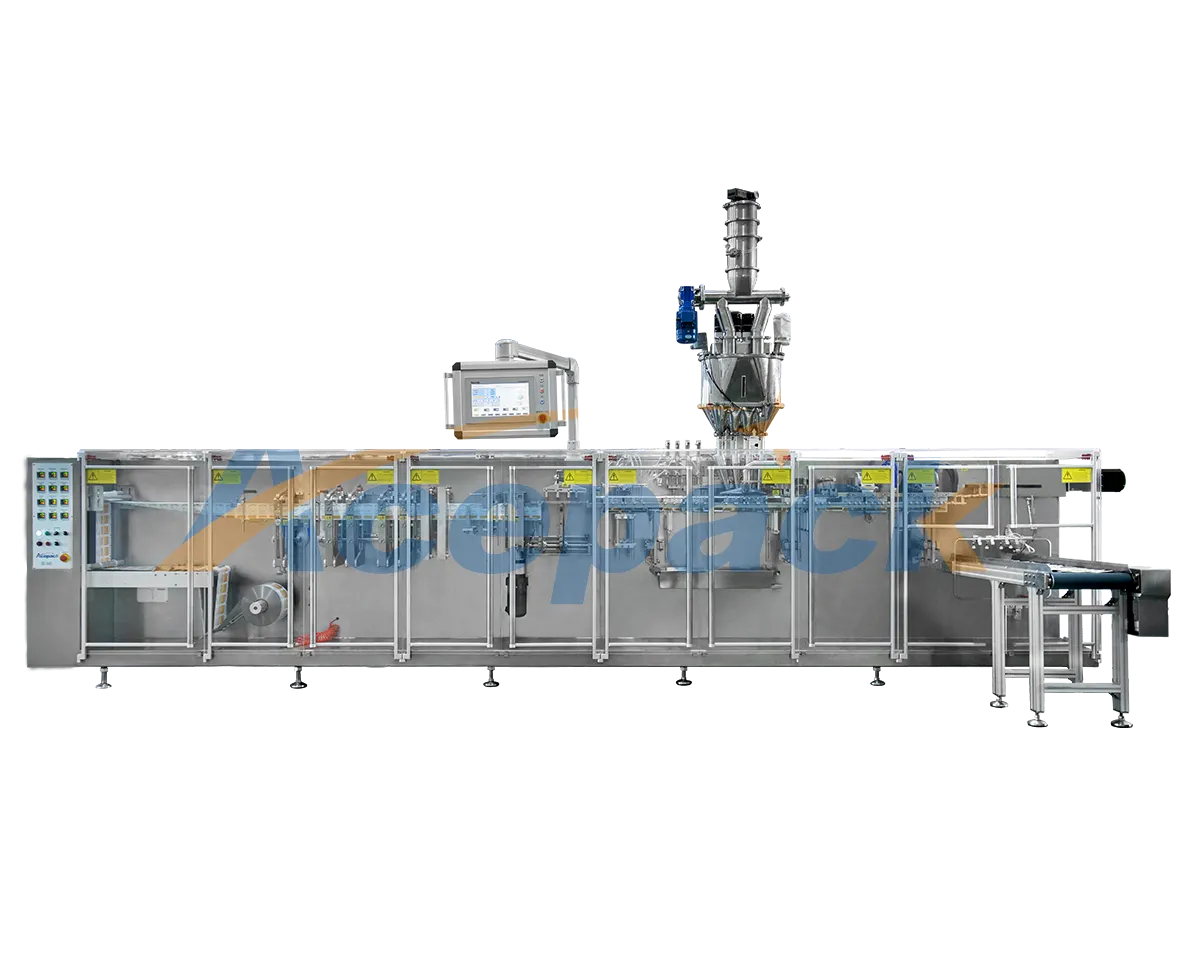

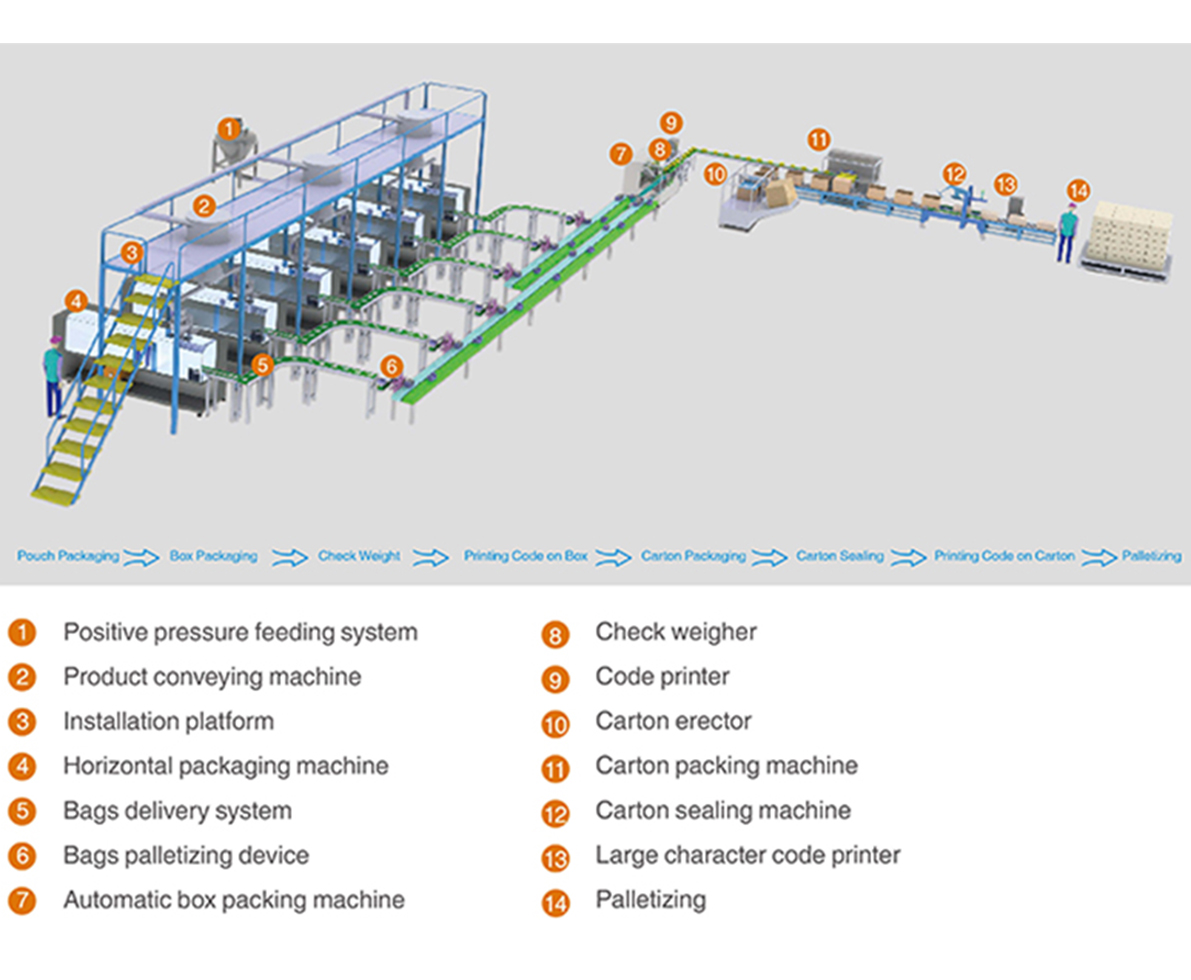

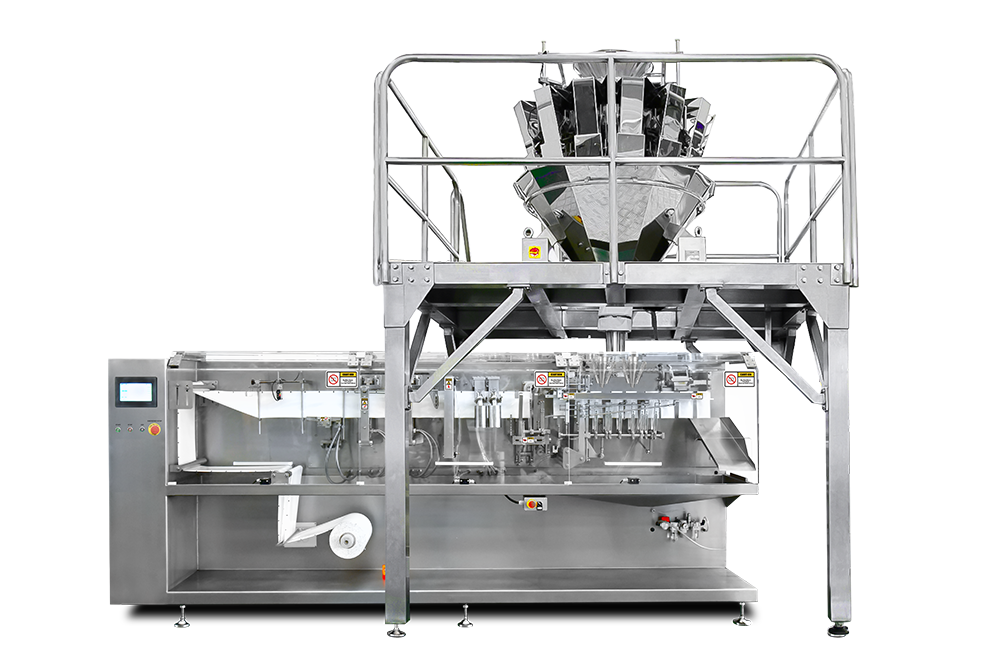

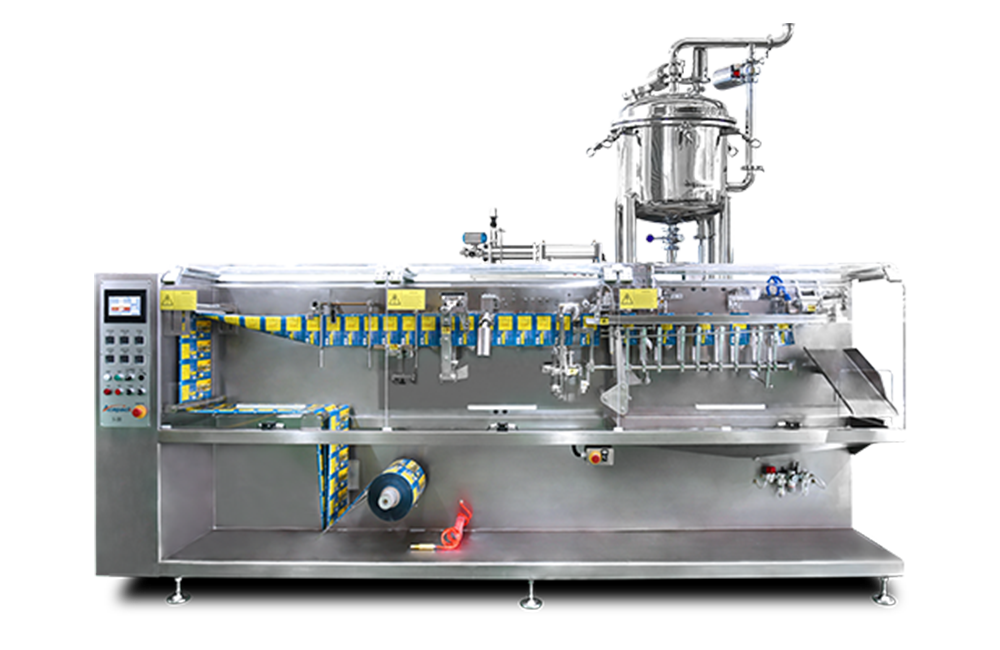

Horizontal packing machine

By using a variety of heat sealable multi-layer complex film, our doypack machine series horizontal FFS packaging machine is designed for packaging doypack (standup pouches) and is fully automatic system for pouch forming, filling, sealing. Equipped with our filling or dosing system, customer can fill various products: powder, liquid or granule.

Acepack packaging machine can achieve three-side sealing, four-side sealing, stand-up pouches, shaped pouches, spout pouches, dual pouches, and other packaging forms. It is suitable for a wide range of industries such as food, pharmaceuticals, health supplements, seasonings, personal care products, and pet food.

How to ensure sealing efficiency.

1.Adjusting machine parameters: Adjust the temperature, pressure, sealing time, and other parameters of the packaging machine according to different packaging materials and product characteristics to ensure good sealing results.

2.Sealing frequency: The equipment includes multiple heat sealing and cold sealing processes to ensure rapid sealing and Customized sealing patterns.

3.High-temperature tape: High-temperature tape is used at the sealing block to prevent material scorching caused by overheating, which could affect the appearance.

Why use stand-up pouch packaging

1.Stand-up pouch packaging can stand at the bottom, making it more visually appealing. More 2.products can be filled inside the stand-up pouch.

Characteristics of spout pouches

1.The mode of filling before adding the spout ensures the aesthetics of the spout and sealing, with no residue.

2.The product is more distinctive, with Customized spout shapes and bag forms.

3.Consumers find it more convenient to use.

Team: We have a professional team with rich experience and strong technical skills, capable of providing high-quality, specialized after-sales services, available 24 hours to serve you.

Personalized Customization:We can tailor solutions according to the specific needs and issues of customers, ensuring that each customer receives a personalized service experience.

Continuous Care: We not only focus on post-sales services after product sales but also emphasize building long-term relationships with customers, continuously providing care and support to ensure ongoing improvement in customer satisfaction.

On-Site Installation and Commissioning: For every equipment sold, our engineers will conduct on-site installation and commissioning to ensure that the equipment is ready for production use at the earliest opportunity.

Machine Training: In addition to initial installation and training sessions and providing training manuals, we also offer regular monthly follow-up training to ensure that customers become proficient in using the packaging equipment.

Maintenance: We provide services for equipment upgrades, replacement of spare parts, and offer a one-year warranty period.