- Doypack Packing Machine

- Sachet Packing Machine

- Premade Bag Packing Machine

- High Speed Sachet Packing Machine

- Full Servo +Flexible Packaging Machine

- Packing Line

- Hand washing Liquid packing machine

- Ultra Clean Milk Product Packing Machine

- Bag Filling and Capping Machine

- Assistant Device

- Vacuum Packing Machine

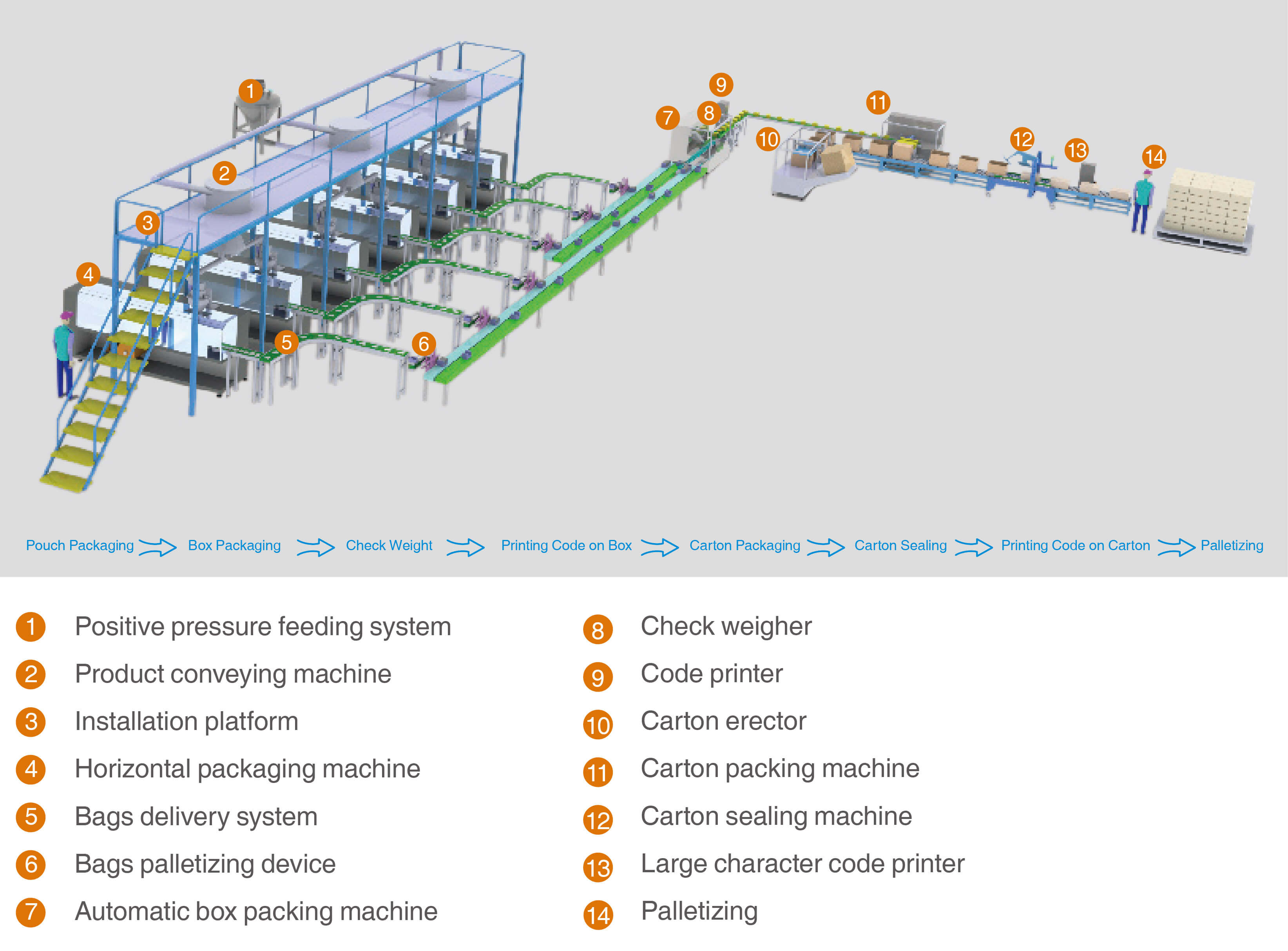

Packing Line

Shanghai Acepack Intelligent Technology Co., Ltd. having advanced design concepts and abundant experience, provide customers with a variety of automatic bags packaging lines. Applied to many industries, our machines are used in the fields of food, beverage, daily chemical, agro-chemical and etc. The customized packaging solutions are provided according to clients’ products characteristic, production process requirements and site conditions. The ideal packaging factories are built up. This project adopts a positive pressure feeding system to feed 6 centralized packaging machines. The Model S-180D (horizontal double bags output packaging machines) automatically pack products in bags at the same time that print the date code. Through the conveying belt, the finished bags are sent to the count and fold device and finally are palletized. Then batches of bags are moved on to the conveying tray line. After that, the rotary pushing device pushes the bags into the feeding belt to the box packaging machine. Finished boxes go through the check weigher where unqualified boxes will be rejected. Small character code is printed on the qualified boxes. Then the boxes are sent to the carton packaging machine, automatically being put in order. Carton erector sent finished cartons to carton packaging machine. Finished cartons are delivered to carton sealing machine to be seal up. Finally the cartons are printed with a big character code and stacked by manual work. The entire line is fully automatic under the control of a central line control system.

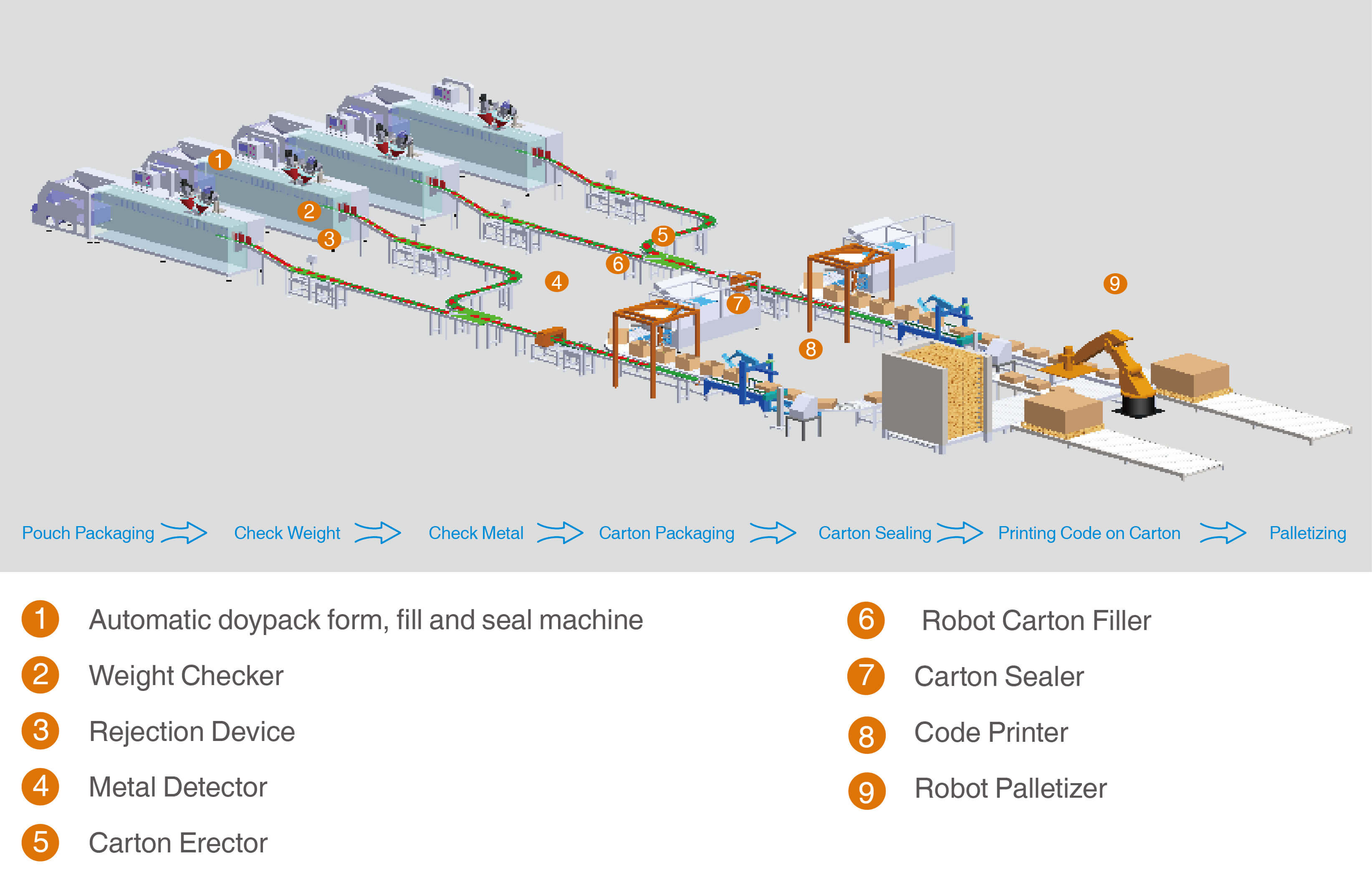

Overall Packaging Solution 2

Shanghai Acepack Intelligent Technology Co., Ltd. having advanced design concepts and abundant experience, provide customers with a variety of automatic bags packaging lines. Applied to many industries, our machines are used in the fields of food, beverage, daily chemical, agro-chemical and etc. The customized packaging solutions are provided according to clients’ products characteristic, production process requirements and site conditions. The ideal packaging factories are built up. It is a overall packaging solution, automatically packing products in doypack by 4 fully automatic horizontal doypack packing machines at the same time printing the date code.Through the conveying belt,finished doypacks go through the weighing system where unqualified doypacks will be rejected. The accepted doypacks will be online metal detected.Then the doypacks are sent to the carton packaging machine,automatically being put in order.Carton erector send the opened carton to carton packaging machine.Finished cartons are delivered to caron sealing machine to be seal up.Finally the cartons are printed with a big character code and palletized by robot palletizer.The entire line is fully automatic under the control of a central line control system.

Products

- Doypack Packing Machine

- Sachet Packing Machine

- Premade Bag Packing Machine

- High Speed Sachet Packing Machine

- Full Servo +Flexible Packaging Machine

- Packing Line

- Hand washing Liquid packing machine

- Ultra Clean Milk Product Packing Machine

- Bag Filling and Capping Machine

- Assistant Device

- Vacuum Packing Machine