What is a Doypack Packaging Machine?

May 19 2025

The Complete Guide to Doypack Packaging Machines

Doypack packaging machines have revolutionized flexible packaging across industries. These specialized machines create stand-up pouches with spouts or zippers - ideal for liquid, powder, and granular products.

Doypack packaging machines have revolutionized flexible packaging across industries. These specialized machines create stand-up pouches with spouts or zippers - ideal for liquid, powder, and granular products.

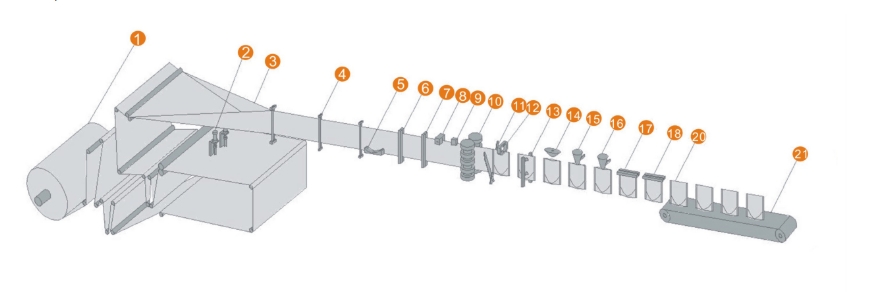

How Doypack Machines Work?

Pouch Formation: Rolls of laminated film are cut and sealed into rectangular pouches

Filling System: Precision auger or liquid pumps dispense measured quantities

Sealing Process: Heat-sealing jaws create airtight closures

Optional Features: Gas flushing, date coding, and quality inspection systems

Pouch Formation: Rolls of laminated film are cut and sealed into rectangular pouches

Filling System: Precision auger or liquid pumps dispense measured quantities

Sealing Process: Heat-sealing jaws create airtight closures

Optional Features: Gas flushing, date coding, and quality inspection systems

Key Applications:

Food Industry: Coffee, snacks, sauces

Pharmaceuticals: Powdered supplements

Chemicals: Detergents, agricultural products

Food Industry: Coffee, snacks, sauces

Pharmaceuticals: Powdered supplements

Chemicals: Detergents, agricultural products

|

Parameter |

Typical Range |

|

Speed |

40-120 pouches/min |

|

Pouch Size |

500ml-2000ml capacity |

|

Power Requirement |

6.5-10kW |

Advantages Over Traditional Packaging

✓ 30% material savings vs rigid containers

✓ Extended shelf life through modified atmosphere

✓ Superior branding space with 360° graphics

Maintenance Requirements

Daily: Cleaning of filling nozzles

Monthly: Lubrication of chain drives

Annual: Servo motor calibration

Cost Considerations

Entry-level models start at 25,000 dollar ,while fully automated lines with vision system scanexceed 150,000. ROI typically achieved in 18-24 months through reduced material costs and increased throughput.

✓ 30% material savings vs rigid containers

✓ Extended shelf life through modified atmosphere

✓ Superior branding space with 360° graphics

Maintenance Requirements

Daily: Cleaning of filling nozzles

Monthly: Lubrication of chain drives

Annual: Servo motor calibration

Cost Considerations

Entry-level models start at 25,000 dollar ,while fully automated lines with vision system scanexceed 150,000. ROI typically achieved in 18-24 months through reduced material costs and increased throughput.