With the development of life and industrial

automation, the traditional machinery industry has undergone earth-shaking

changes. The phenomenon of high degree of mechanical automation and replacement

of labor by machines is becoming more and more common. This change is most

prominent in the field of packaging machinery. In the past, semi-automatic

packaging or more backward manual packaging was generally used. Compared with

fully automatic packaging, this method has many disadvantages. First of all,

due to the poor packaging environment, heavy dust, and labor High strength, it

will cause certain harm to the human body; then the measurement error of manual

packaging and semi-automatic packaging is much larger than that of fully

automatic packaging; the efficiency of manual packaging and semi-automatic

packaging is lower in packaging speed, and it is more and more unsatisfactory.

Production needs. What is needed now is a fully automatic packaging machine. Do

you know what are the advantages of the fully automatic packaging machine?

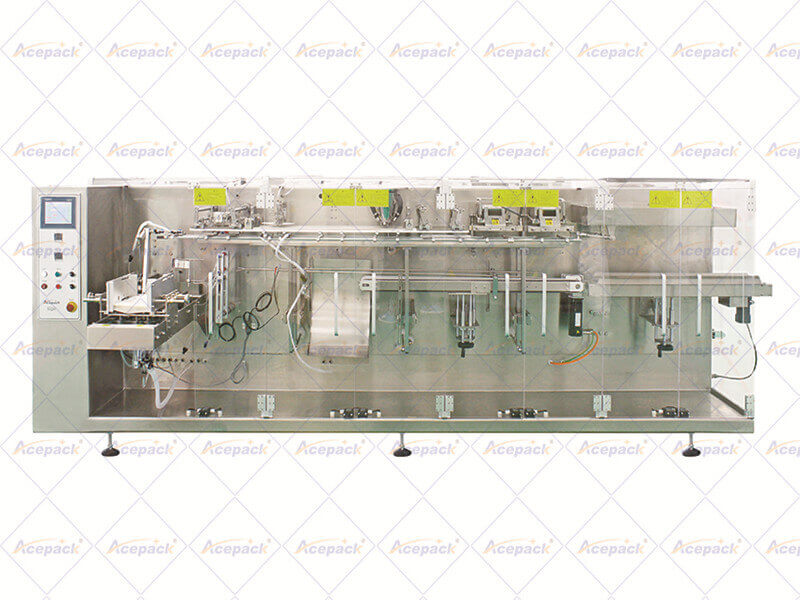

At present, the outstanding advantages of the automatic packaging machine are mainly: 1. High efficiency: The automatic packaging machine can efficiently complete all the production processes of feeding, metering, bagging, printing date, and product output. The automatic packaging machine has high measurement accuracy, It is fast in efficiency, saves materials and also reduces labor costs. 2. Reduce labor intensity: The automatic packaging machine replaces manual packaging to free workers from heavy work. First of all, manual packaging of some bulky and heavy products consumes physical strength and is easily injured; secondly, some products produce dust, radioactivity, and irritating hazards to the human body during the production process. Automatic packaging machines can effectively solve these problems. 3. Energy saving and environmental protection: Generally speaking, the fully automatic packaging machine with good service has the function of automatic detection. Therefore, for those unqualified products, the machine can intelligently automatically screen and repackage again, which improves the pass rate while not Waste materials, while reducing wastage, it is also convenient for maintenance and operation, which greatly reduces production costs. 4. Safety and health: It is difficult for manual packaging to avoid contact between people and production products due to manual participation, which may contaminate the products and make it difficult to guarantee production quality. The automatic packaging machine has no human participation in the whole process from feeding to finished products. This packaging production line reduces the bacterial contamination of the packaging process and provides a good guarantee for the reputation of the company.

Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. has more than ten years of experience in packaging. We are not afraid of wind and rain and persevere in order to make a good packaging machine for customers to have a good experience. If you think the above is not enough, you are welcome You contact us, we will solve the problem for you!