Nowadays, life is getting better and

better. More and more people have very high requirements for the quality of

life. Everything needs external packaging to become gorgeous. These are

indispensable for packaging machines. There are many types of packaging

machines on the market. A packaging machine has its own purpose. I believe that

many people don’t understand the current hot liquid packaging machine, let

alone its use, characteristics and what should be paid attention to when using

it. Since we don’t know the above, we are Shanghai Acepack packing machine

company Smart Packaging Technology Co., Ltd. takes you to understand the liquid

packaging machine.

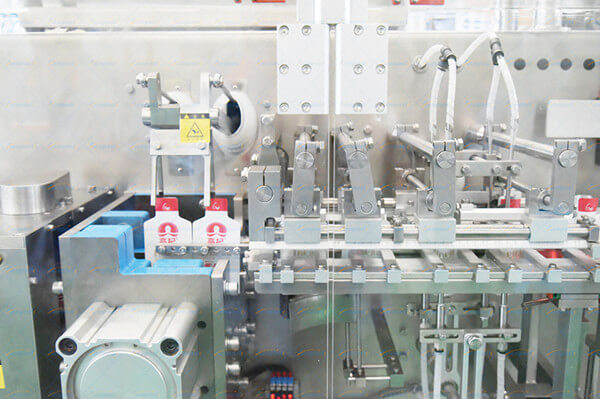

First of all, we are talking about the use of liquid packaging machines. It summarizes a lot: 1. Liquid packaging machines are packaging equipment for packaging liquid products, such as beverage filling machines, dairy filling machines, viscous liquid food packaging machines, liquid cleaning products And personal care product packaging machines, etc. belong to the category of liquid packaging machines. 2. It is suitable for soy sauce, vinegar, juice, milk and other liquids. The processes of forming, bag making, quantitative filling, ink printing, sealing and cutting are all performed automatically. The film is sterilized by ultraviolet light before packaging, which meets the requirements of food hygiene.

Then we talk about its characteristics and what we should pay attention to when using it. Let's talk about its characteristics first. Its characteristics are very simple and not complicated. The liquid packaging machine's process parts are all made of stainless steel, and the high-level balance tank or self-priming pump is used for quantitative Filling, direct heat sealing and cutting, convenient and reliable adjustment of bag size, packaging weight, sealing and cutting temperature, production date ribbon printing, side sealing and back sealing, photoelectric tracking. Then let's talk about what we should pay attention to when using it: 1. Before starting each time, check and observe whether there are abnormalities around the machine. 2. When the machine is in operation, it is strictly forbidden to approach or touch the moving parts with your body, hands and head. 3. When the machine is in operation, it is strictly forbidden to extend hands and tools into the sealing knife seat. 4. It is strictly forbidden to switch the operation buttons frequently during normal operation of the machine, and it is strictly forbidden to change the parameter setting value at will. 5. Long-term operation at super high speed is strictly prohibited. 6. It is forbidden for two people to operate the various switch buttons and mechanisms of the machine at the same time; the power should be turned off during maintenance and maintenance; when multiple people are debugging and repairing the machine at the same time, they must communicate with each other and indicate to prevent accidents caused by incoordination. 7. When checking and repairing electrical control circuits, it is strictly forbidden to work with electricity! Be sure to cut off the power! It must be done by electrical professionals, and the machine is automatically locked by the program and cannot be modified without authorization. 8. When the operator is unable to stay awake due to drinking or fatigue, operation, debugging or maintenance is strictly prohibited; other untrained or unqualified personnel are not allowed to operate the machine.