In the fast-paced world of packaging, selecting the right equipment is crucial for ensuring efficiency, quality, and compliance with industry standards. For businesses looking to package products in stick form, a stick packing machine is an essential investment. With various options available, including customizable stick packing machines and multi-lane stick packing machines, it’s important to understand how to choose the best stick packing machine for your specific product needs.

Understanding Stick Packing Machines

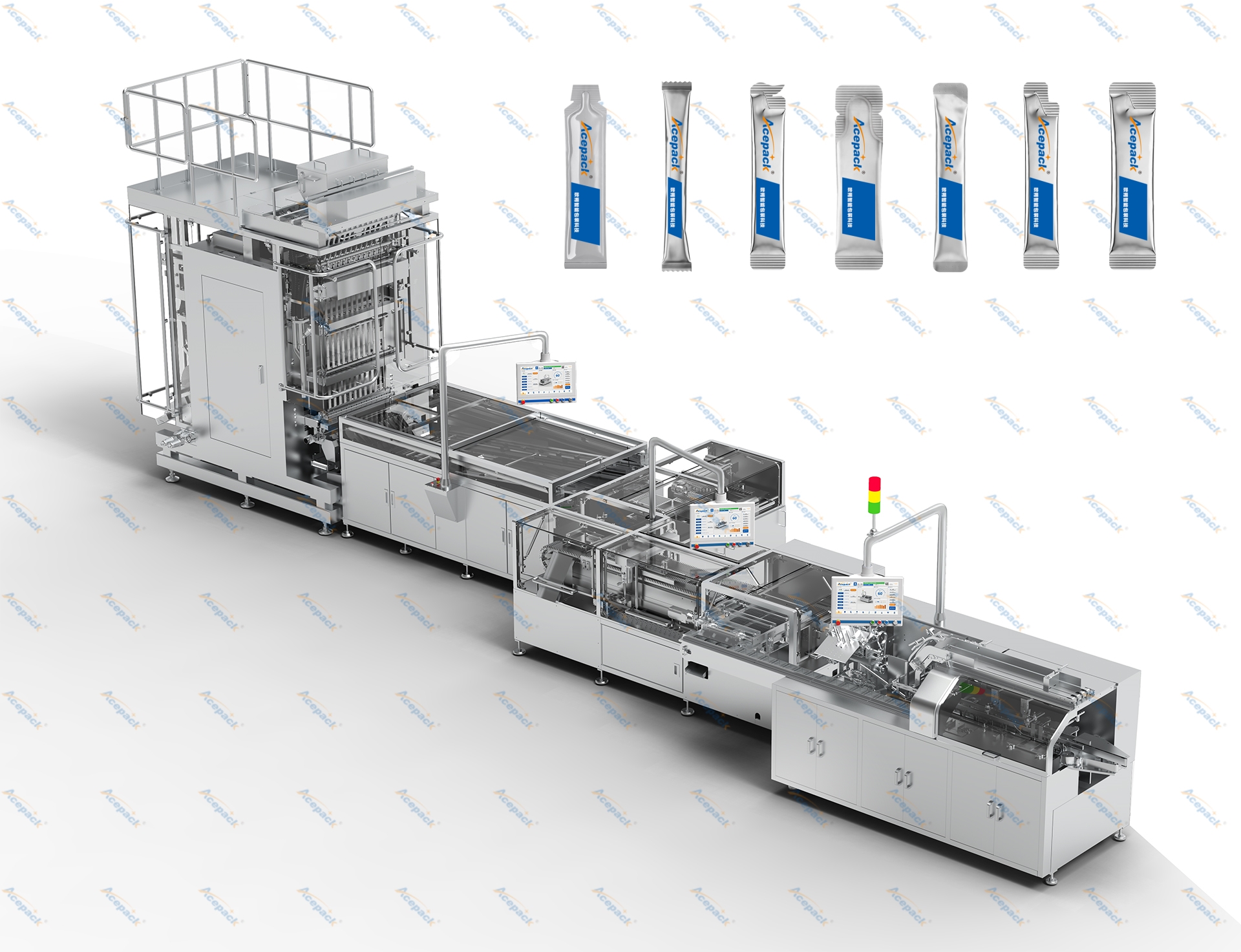

Stick packing machines are designed to package products into stick-shaped pouches, which are commonly used for items like powders, granules, and liquids. These machines can be tailored to meet the unique requirements of different products, making them a versatile choice for manufacturers.

Customizable Stick Packing Machines

One of the most significant advantages of modern stick packing machines is their customizable features. Customizable stick packing machines allow businesses to achieve various metering methods, ensuring that the right amount of product is packaged every time. This flexibility is particularly beneficial for companies that offer a range of products or those that frequently change their product lines.

When considering a customizable stick packing machine, look for features that allow you to adjust the metering methods easily. This will enable you to switch between different products without the need for extensive reconfiguration, saving time and reducing downtime during production.

Multi-Lane Stick Packing Machines

For businesses with high production demands, a multi-lane stick packing machine can be an excellent choice. These machines can operate multiple lanes simultaneously, significantly increasing output and efficiency. A stable speed of 70-80 cuts per minute is achievable with these machines, allowing for rapid packaging without compromising quality.

When selecting a multi-lane stick packing machine, consider the number of lanes you require based on your production volume. Additionally, ensure that the machine can accommodate the specific dimensions and characteristics of your product, as this will impact the overall efficiency of your packaging process.

Key Features to Consider

When choosing the best stick packing machine for your product, several key features should be taken into account:

1. Metering Methods

As mentioned earlier, the ability to achieve various customized metering methods is crucial. Depending on your product, you may need to package powders, granules, or liquids, each requiring different metering techniques. Ensure that the machine you choose can handle your specific product type effectively.

2. Data Management and Compliance

In today’s regulatory environment, compliance with EHS (Environmental, Health, and Safety) management requirements is essential. Look for stick packing machines that meet these standards and offer features such as audit trails and data statistics. These functionalities will help you maintain compliance and improve your overall operational efficiency.

3. User-Friendly Interface

An 18.5-inch large industrial control screen is a valuable feature that enhances usability. A user-friendly interface allows operators to monitor and control the machine easily, reducing the likelihood of errors and improving overall productivity. Look for machines that offer intuitive controls and clear displays for optimal operation.

4. Human-Machine Interaction

A full servo control system enhances Overall Equipment Effectiveness (OEE) by providing precise control over the packaging process. This technology allows for better synchronization between different machine components, resulting in smoother operation and reduced wear and tear on the equipment.

5. Speed and Efficiency

The speed of the stick packing machine is a critical factor in determining its efficiency. Machines that can achieve stable speeds of 70-80 cuts per minute can significantly boost your production capabilities. However, it’s essential to balance speed with the quality of the packaging to ensure that your products are packaged correctly and securely.

Choosing the best stick packing machine for your product involves careful consideration of various factors, including customization options, production speed, compliance with regulations, and user-friendliness. By focusing on these key features, you can select a machine that not only meets your current needs but also adapts to future changes in your product line.

Investing in a high-quality stick packing machine, whether it’s a customizable model or a multi-lane option, can lead to increased efficiency, reduced operational costs, and improved product quality. Take the time to evaluate your specific requirements and choose a machine that aligns with your business goals. With the right stick packing machine, you can streamline your packaging process and enhance your overall productivity.