In the fast-paced world of packaging, efficiency and precision are paramount. One of the most innovative solutions that have emerged in recent years is the sachet packing machine. This versatile equipment is designed to package a variety of products into flat sachets, making it an essential tool for many industries, including food, pharmaceuticals, and cosmetics. In this article, we will explore how a sachet packing machine works, focusing on different types such as the Flat Sachet Packaging Machine, Twin-sachet Pouch Packing Machine, and Zipper Flat Sachet Packaging Machine.

Understanding Sachet Packing Machines

A sachet packing machine is a specialized device that automates the process of filling and sealing products into small, flat pouches or sachets. These machines are designed to handle a wide range of materials, from powders and granules to liquids and pastes. The primary goal of a sachet packing machine is to ensure that products are securely packaged, preserving their quality and extending their shelf life.

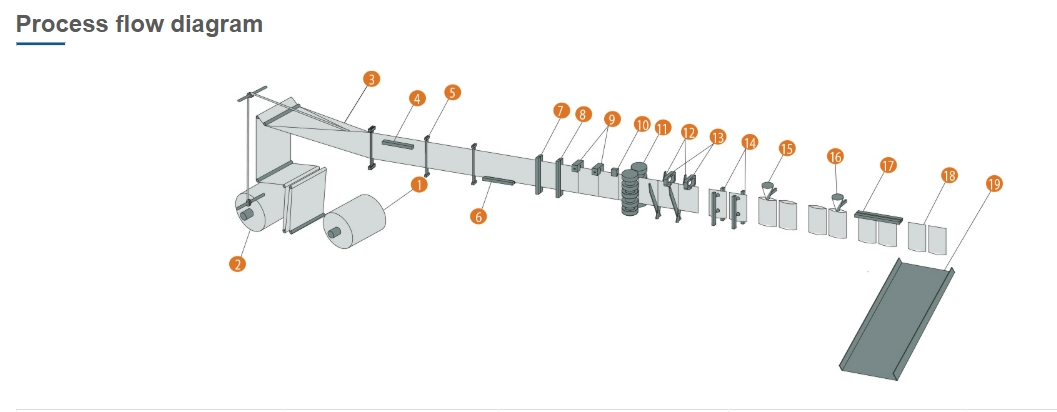

Components of a Sachet Packing Machine

To understand how a sachet packing machine works, it is essential to familiarize ourselves with its key components:

-

Feeding System: This component is responsible for delivering the product to be packaged into the machine. Depending on the type of product, the feeding system can vary. For instance, a powder feeder may be used for powdered products, while a liquid pump is used for liquids.

-

Forming Tube: The forming tube is where the packaging material is shaped into a pouch. The material, usually a roll of plastic film, is fed into the machine and formed into a tube that will eventually become the sachet.

-

Filling System: Once the pouch is formed, the filling system dispenses the product into the sachet. This can be done using various methods, such as volumetric filling for powders or liquid filling for liquids.

-

Sealing Mechanism: After the product is filled, the sachet must be sealed to ensure it remains airtight. The sealing mechanism uses heat or pressure to bond the edges of the sachet, preventing any leakage or contamination.

-

Cutting System: Finally, the cutting system separates individual sachets from the continuous roll of pouches, allowing for easy handling and distribution.

Types of Sachet Packing Machines

-

Flat Sachet Packaging Machine: This type of machine is designed to create flat sachets that are ideal for single-serving products. The Flat Sachet Packaging Machine is particularly popular in the food industry for packaging items like sugar, salt, and condiments. The machine operates by forming a flat pouch, filling it with the product, sealing it, and cutting it into individual sachets.

-

Twin-sachet Pouch Packing Machine: The Twin-sachet Pouch Packing Machine is an advanced version that can produce two sachets simultaneously. This machine is perfect for products that are often sold in pairs, such as sauces or seasoning mixes. By doubling the output, manufacturers can significantly increase their production efficiency while maintaining high-quality packaging.

-

Zipper Flat Sachet Packaging Machine: This machine adds an extra layer of convenience by incorporating a zipper feature into the sachet. The Zipper Flat Sachet Packaging Machine is ideal for products that need to be resealed after opening, such as snacks or pet food. The zipper allows consumers to easily access the product while keeping it fresh for longer periods.

The Working Process of a Sachet Packing Machine

The operation of a sachet packing machine can be broken down into several key steps:

-

Material Loading: The packaging material is loaded onto the machine, and the product is prepared for filling.

-

Forming the Pouch: The machine pulls the film from the roll and forms it into a tube using the forming tube. The edges of the film are then sealed to create a continuous pouch.

-

Filling the Pouch: The filling system dispenses the product into the formed pouch. This step is crucial, as accurate filling ensures that each sachet contains the correct amount of product.

-

Sealing the Pouch: After filling, the machine seals the top of the pouch using heat or pressure, creating an airtight seal.

-

Cutting the Sachets: The machine then cuts the sealed pouches into individual sachets, ready for packaging and distribution.

-

Quality Control: Many modern sachet packing machines are equipped with sensors and cameras to ensure that each sachet meets quality standards. This includes checking for proper sealing, correct fill levels, and overall appearance.