At present,

whether it is in the production of medicines, the food industry, and the daily

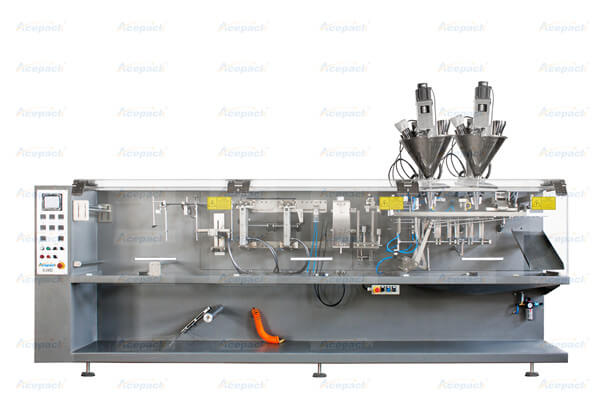

chemical industry. Powder packaging machines are widely used. Domestic powder

packaging machines are constantly improving themselves on the basis of the

past, aiming at humanized operation, focusing on the perfect combination of

product quality and appearance, and making great contributions to my country's

powder packaging machines.

After purchasing the powder packaging machine, pay attention to its daily maintenance and maintenance to ensure the normal operation of the equipment and extend the service life of the equipment. Shanghai Acepack packing machine company analyzes several major issues that need attention in the maintenance of powder packaging machines.

1. Lubrication work. When using the powder packaging machine, lubricate the gear meshes, the oil hole of the bearing with a seat and all the moving parts on a regular basis. It is forbidden to run the reducer without oil every shift. When adding lubricating oil, be careful not to put the oil tank on the rotating belt to prevent slipping and loss of rotation or premature aging of the belt and damage.

2. maintenance work. Before using the powder packaging machine, check the screws at all parts, and there must be no looseness, otherwise, it will affect the normal long-distance rotation of the whole machine. The electrical parts should be waterproof, moisture-proof, anti-corrosion, and rodent-proof. In order to ensure that the inside of the electric control box and the wiring terminals are clean to prevent electrical failures, after the shutdown, the two heat sealers should be in the open position to prevent scalding the packaging materials.

3. cleaning job. After the powder packaging machine is shut down, the metering part should be cleaned in time, and the heat sealer body should be cleaned frequently to ensure that the sealing lines of the packaged product are clear. The scattered materials should be cleaned up in time to facilitate the cleanness of the machine parts. It is better to extend its service life, and at the same time clean the dust in the electric control box frequently to prevent electrical faults such as short circuits or poor contacts.

In general, the powder packaging machine is closely related to our lives. It can not only ensure the smooth progress of the packaging work, but also obtain satisfactory packaging effects, but also cleaner people's working environment, making people safe and healthy at work. In order to ensure the long-term operation of this powder packaging machine, we must pay attention to its daily maintenance so that it can better serve our production and life.

If you are interested in our Shanghai Acepack packing machine company powder packaging machine, please ask us!