The demand for flexible, resealable packaging is growing rapidly across industries like food, pharmaceuticals, and cosmetics. A zipper pouch packing machine has become an essential tool for businesses aiming to deliver convenience and freshness to customers. In this guide, we’ll explore how these machines work, their advantages, and how to choose the best one for your needs.

What is a Zipper Pouch Packing Machine?

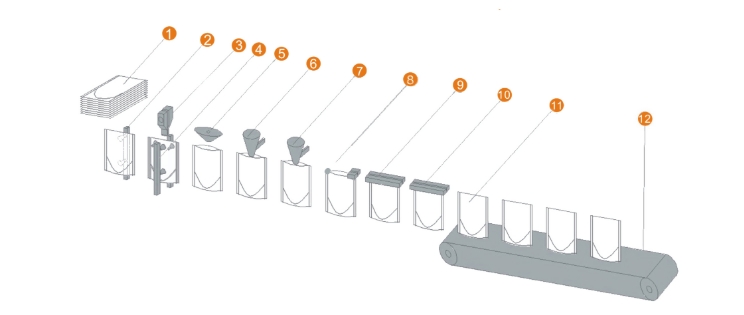

A zipper pouch packing machine automates the process of filling and sealing stand-up or flat pouches with resealable zippers. These machines handle tasks like:

-

Pouch forming (for premade or roll-fed pouches)

-

Precision filling (liquids, powders, or solids)

-

Zipper alignment and sealing

-

Date coding and labeling

-

They are ideal for products requiring repeated access, such as snacks, coffee, pet food, or medical supplies.

Top Benefits of Using a Zipper Pouch Packing Machine

-

Extended Shelf Life: Airtight zipper seals prevent moisture, oxygen, and contaminants.

-

Consumer Convenience: Resealable pouches improve user experience and brand loyalty.

-

Reduced Waste: Customers can reuse pouches, aligning with sustainability goals.

-

High Efficiency: Machines can pack 30–100 pouches per minute, depending on the model.

-

Types of Zipper Pouch Packing Machines

-

Horizontal Form-Fill-Seal (HFFS) Machines

-

Create pouches from film rolls.

-

Suitable for small to medium businesses.

-

Cost-effective but may require manual zipper insertion.

-

-

Premade Pouch Machines

-

Use prefabricated zipper pouches.

-

Ideal for delicate products (e.g., electronics, luxury items).

-

Higher speed but pricier pouches.

-

-

Automatic Zipper Applicator Machines

-

Add zippers to existing packaging lines.

-

Compatible with most pouch styles.

-

Key Features to Consider When Buying

-

Speed: Match output to your production goals (e.g., 50 vs. 200 pouches/minute).

-

Zipper Compatibility: Ensure the machine supports slider or press-to-close zippers.

-

Material Flexibility: Check if it handles multilayer films, aluminum laminates, or biodegradable materials.

-

Automation Level: Options include semi-automatic (manual loading) or fully automatic (robotic integration).

Popular Google Questions Answered

Q: How much does a zipper pouch packing machine cost?

A: Prices range from 15,000 for basic models to100,000+ for high-speed, fully automated systems.

Q: Can these machines handle liquids?

A: Yes, but ensure the machine has liquid filling nozzles and drip-proof mechanisms.

Q: What maintenance is required?

A: Daily cleaning, weekly lubrication, and periodic part replacement (e.g., sealing jaws).

Final Tips for Buyers

-

Request a live demo to test pouch quality.

-

-

Prioritize suppliers with strong after-sales support.

-

Consider energy efficiency to reduce long-term costs.

Investing in a zipper pouch packing machine can elevate your packaging quality and operational efficiency. Assess your product requirements and budget to make an informed choice.