In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the most innovative solutions that have emerged in recent years is the powder premade pouch packing machine. But what exactly is this machine, and how does it transform the way we package powdered products? In this blog, we will explore the intricacies of powder premade pouch packing machines, their benefits, and their impact on various industries.

What is a Powder Premade Pouch Packing Machine?

A powder premade pouch packing machine is a specialized piece of equipment designed to fill and seal pre-made pouches with powdered products. These machines are engineered to handle a variety of powders, including food items like spices, flour, and protein powders, as well as non-food items such as chemicals and pharmaceuticals. The machine operates by taking pre-formed pouches, filling them with the desired powder, and then sealing them to ensure freshness and prevent contamination.

How Does a Powder Premade Pouch Packing Machine Work?

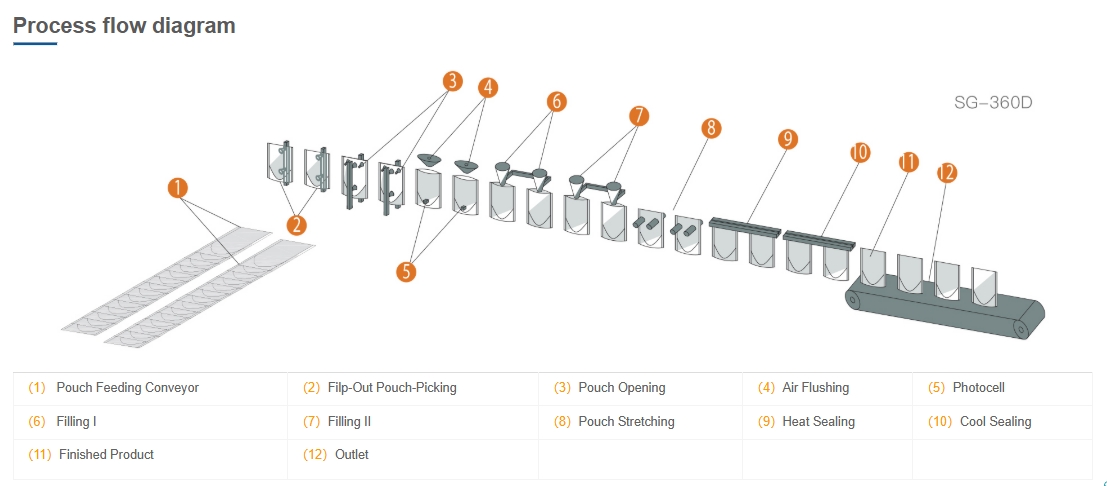

The operation of a powder premade pouch packing machine can be broken down into several key steps:

-

Pouch Feeding: The process begins with the feeding of pre-made pouches into the machine. These pouches can be made from various materials, including plastic, foil, or paper, depending on the product’s requirements.

-

Filling: Once the pouches are in place, the machine uses a filling mechanism to dispense the powdered product into each pouch. This can be done using auger fillers, volumetric fillers, or other specialized filling systems that ensure accurate measurements and minimize waste.

-

Sealing: After the pouches are filled, the machine seals them using heat or pressure, depending on the pouch material. This step is crucial for maintaining the product’s integrity and extending its shelf life.

-

Cutting and Discharge: Finally, the machine may cut the pouches from a roll if they are not pre-made, and then discharge the finished products for packaging or shipping.

Why Choose a Powder Premade Pouch Packing Machine?

The adoption of powder premade pouch packing machines offers numerous advantages for manufacturers and businesses. Here are some compelling reasons to consider this technology:

-

Efficiency: These machines are designed for high-speed operation, allowing businesses to package large quantities of product in a short amount of time. This efficiency can significantly reduce labor costs and increase overall productivity.

-

Precision: With advanced filling mechanisms, powder premade pouch packing machines ensure accurate measurements, minimizing product waste and ensuring consistency in each pouch. This precision is particularly important in industries where dosage matters, such as pharmaceuticals.

-

Versatility: These machines can handle a wide range of powdered products, making them suitable for various industries. Whether you are packaging food, cosmetics, or industrial chemicals, a powder premade pouch packing machine can be tailored to meet your specific needs.

-

Reduced Material Waste: By using pre-made pouches, manufacturers can reduce the amount of packaging material wasted during the production process. This not only saves costs but also contributes to more sustainable packaging practices.

-

Enhanced Product Protection: The sealing process used in these machines ensures that the products are protected from moisture, air, and contaminants, which is essential for maintaining product quality and extending shelf life.

What Industries Benefit from Powder Premade Pouch Packing Machines?

The versatility of powder premade pouch packing machines means they are utilized across a wide range of industries. Here are a few sectors that particularly benefit from this technology:

-

Food and Beverage: The food industry relies heavily on powder packaging for products like spices, instant soups, and protein powders. The ability to maintain freshness and prevent contamination is crucial in this sector.

-

Pharmaceuticals: In the pharmaceutical industry, precise dosing is essential. Powder premade pouch packing machines ensure that each pouch contains the correct amount of medication, which is vital for patient safety.

-

Cosmetics: Many cosmetic products, such as face powders and dry shampoos, are packaged in powder form. These machines help maintain the quality and integrity of these products while providing an attractive packaging solution.

-

Chemicals: The chemical industry often requires the packaging of powdered substances for industrial use. Powder premade pouch packing machines can handle hazardous materials safely and efficiently.

How to Choose the Right Powder Premade Pouch Packing Machine?

When selecting a powder premade pouch packing machine, several factors should be considered:

-

Product Type: Different machines are designed for different types of powders. Ensure that the machine you choose is compatible with your specific product.

-

Production Volume: Consider your production needs. High-speed machines are ideal for large-scale operations, while smaller machines may suffice for lower volumes.

-

Budget: Determine your budget for the machine and consider the long-term savings associated with increased efficiency and reduced waste.

-

Customization: Look for machines that offer customization options to meet your specific packaging requirements.

Conclusion

In conclusion, powder premade pouch packing machines are a game-changer in the packaging industry. Their efficiency, precision, and versatility make them an invaluable asset for businesses across various sectors. By understanding what these machines are and how they work, manufacturers can make informed decisions that enhance their packaging processes and ultimately improve their bottom line. As technology continues to evolve, we can expect even more innovations in the realm of packaging, further revolutionizing how we bring products to market.