In the ever-evolving landscape of the food and beverage industry, the demand for probiotics has surged, driven by a growing awareness of their health benefits. As businesses strive to meet this demand, the packaging of probiotic products has become a critical factor in ensuring product integrity, shelf life, and consumer appeal. One innovative solution that has emerged is the use of probiotics stick pack packaging machines. These machines not only enhance the efficiency of the packaging process but also offer a range of benefits that can significantly impact your business’s bottom line.

Customized Metering Methods

One of the standout features of probiotics stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows businesses to tailor their packaging processes to meet specific product requirements. Whether you are dealing with powders, granules, or liquids, these machines can be adjusted to ensure precise filling, minimizing waste and maximizing efficiency. This level of customization is particularly beneficial for companies that offer a diverse range of probiotic products, as it allows for quick adjustments without the need for extensive reconfiguration.

Compliance and Traceability

In an industry where safety and compliance are paramount, probiotics stick pack packaging machines come equipped with functions such as audit trails, electronic signatures, and data statistics. These features not only help businesses adhere to regulatory requirements but also enhance traceability throughout the supply chain. By maintaining detailed records of the packaging process, companies can ensure that their products meet safety standards and can quickly address any potential issues that may arise. This level of transparency is increasingly important to consumers who are becoming more discerning about the products they choose to purchase.

User-Friendly Interface

The design of probiotics stick pack packaging machines has evolved to prioritize user experience. With an 18.5-inch large industrial control screen and a newly designed human-machine interface, operators can easily navigate the machine’s functions and settings. This user-friendly interface reduces the learning curve for new employees and minimizes the risk of errors during operation. As a result, businesses can achieve higher productivity levels while ensuring that their packaging processes run smoothly.

Enhanced Overall Equipment Effectiveness (OEE)

The full servo control system integrated into probiotics stick pack packaging machines significantly enhances Overall Equipment Effectiveness (OEE). By optimizing the performance of the machine, businesses can achieve higher output rates while reducing downtime. The ability to operate at speeds of 70-80 cuts per minute means that companies can meet high demand without compromising on quality. This efficiency not only improves production timelines but also allows businesses to respond more effectively to market trends and consumer preferences.

Environmental Health and Safety (EHS) Management

In today’s environmentally conscious market, businesses must prioritize sustainability and safety. Probiotics stick pack packaging machines are designed with EHS management requirements in mind. By incorporating features that minimize waste and energy consumption, these machines help businesses reduce their environmental footprint. Additionally, the automated nitrogen filling function, which controls residual oxygen levels within 2%, ensures that probiotic products maintain their potency and shelf life. This commitment to sustainability not only benefits the planet but also enhances a company’s reputation among eco-conscious consumers.

Customized End-to-End Solutions

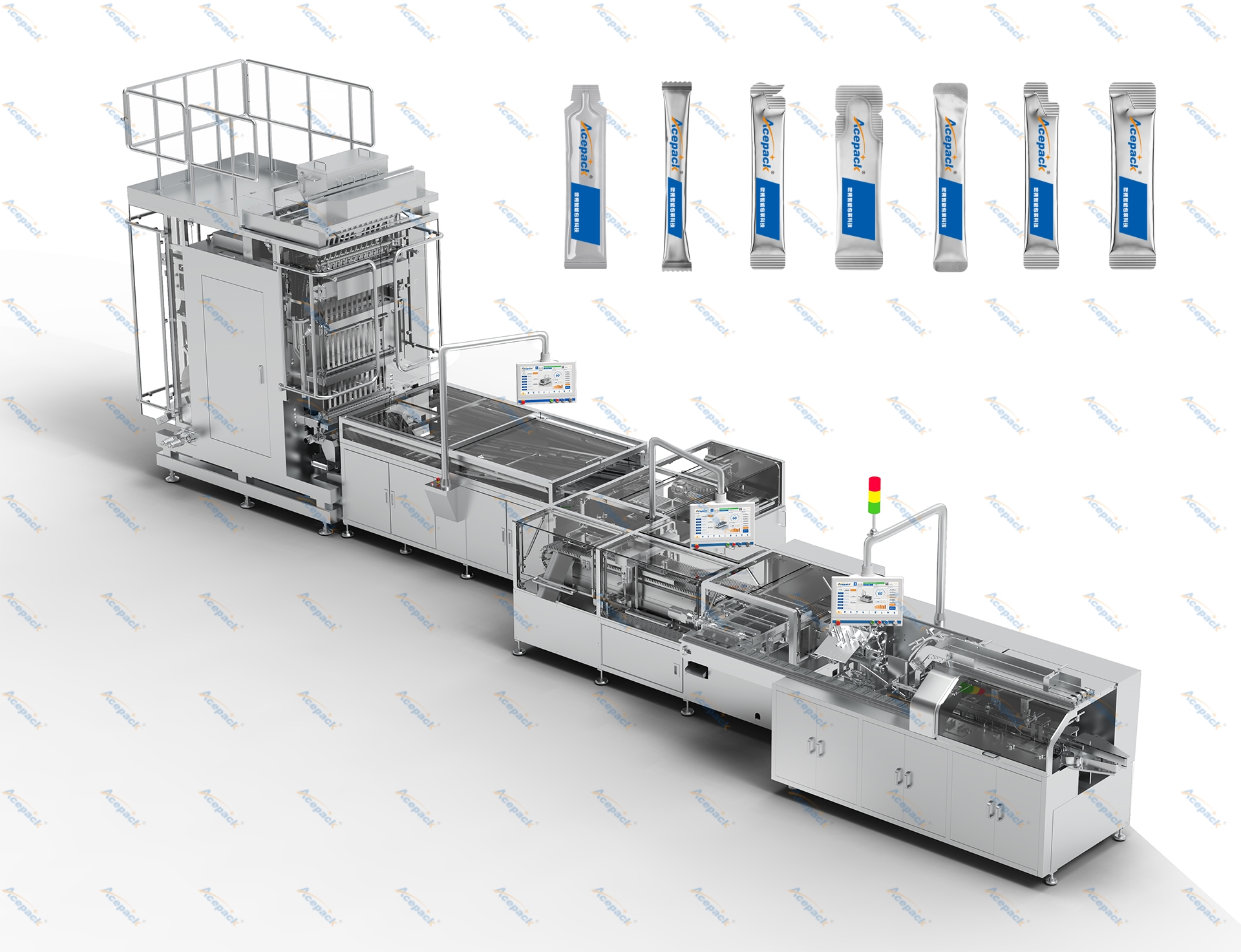

Every business has unique needs, and probiotics stick pack packaging machines offer customized end-to-end solutions that cater to those requirements. From initial design to final packaging, these machines can be tailored to fit specific production lines and product types. This level of customization ensures that businesses can streamline their operations and achieve optimal results. Whether you are a small startup or a large-scale manufacturer, the ability to adapt packaging processes to your specific needs can provide a significant competitive advantage.