Types of Sachet Packaging Machines

-

Liquid Sachet Machines

Designed for viscous or free-flowing liquids like sauces, shampoos, or oils, these machines ensure leak-proof packaging. Key features include:

-

Precision nozzles to prevent spillage.

-

Advanced sealing technology for airtight packaging.

-

Compatibility with multi-layered films for extended shelf life.

-

Granule Filler Sachet Machines

Ideal for granular products such as spices, seeds, or powdered supplements, these machines offer high-speed filling with minimal waste. Notable capabilities include:

-

Volumetric or auger-based filling systems for accuracy.

-

Adjustable portion control for diverse product sizes.

-

Dust extraction mechanisms to maintain hygiene.

-

Powder Sachet Machines

Though not listed as a focus keyword, powder variants complement the lineup with specialized hoppers and anti-static systems.

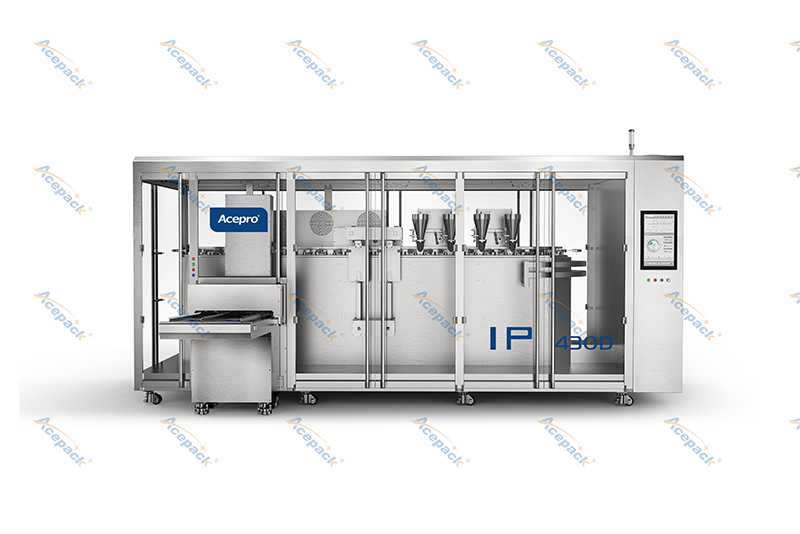

Key Advantages of Modern Sachet Packaging Machines

Modern Sachet Packaging Machines integrate cutting-edge technologies to maximize efficiency. Let’s explore their standout features:

Equipment Features and Parameters

-

Servo Bag Feeding & Fully Servo Structure

-

Ensures stable operation and high control precision, reducing material waste.

-

Simplified mechanics lower noise levels, creating a safer workplace.

-

-

Lifecycle Management & OEE Optimization

-

IoT-enabled devices allow remote monitoring of machine health, minimizing downtime.

-

A fully upgraded control system boosts Overall Equipment Effectiveness (OEE) by 25–30%.

-

-

Enhanced Safety and Intelligence

-

Real-time mechanism monitoring prevents malfunctions.

-

User-friendly interfaces reduce operator dependency, lowering labor costs.

-

Why Invest in Advanced Sachet Machines?

Businesses leveraging these machines report faster ROI due to:

-

Higher Speeds: Process up to 200 sachets/minute.

-

Flexibility: Quick changeovers between liquid and granule products.

-

Sustainability: Precision filling reduces material overuse.

Conclusion

From Liquid Sachet Machines to Granule Filler Sachet Machines, selecting the right equipment depends on product type and scalability needs. With features like servo-driven mechanisms and smart monitoring, modern sachet packaging solutions are indispensable for competitive industries.