When it comes to the production of tomato ketchup, efficiency and quality are paramount. One of the key players in this process is the Horizontal Form Fill Seal (HFFS) machine. In this blog, we will explore the various aspects of HFFS machines specifically designed for tomato ketchup production through a question-and-answer format.

What is an HFFS machine?

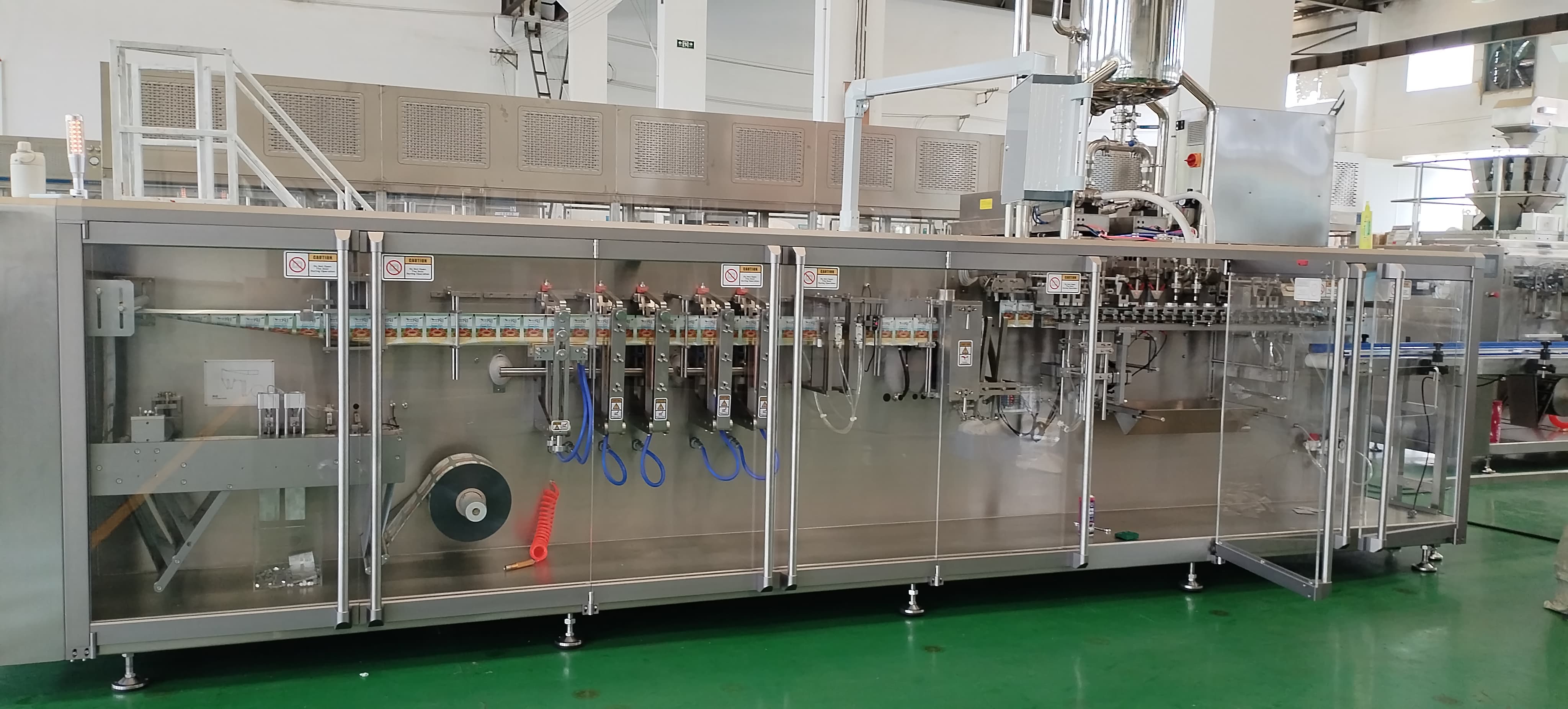

An HFFS machine is a type of packaging equipment that forms, fills, and seals pouches or bags in a horizontal orientation. It is widely used in the food industry, particularly for liquid products like tomato ketchup. The machine operates by unwinding a roll of film, forming it into a pouch, filling it with the product, and then sealing it, all in a continuous process.

Why are HFFS machines preferred for tomato ketchup production?

HFFS machines are preferred for several reasons. Firstly, they offer high-speed production capabilities, which is essential for meeting the demands of large-scale ketchup production. Secondly, they provide excellent sealing quality, ensuring that the product remains fresh and free from contamination. Lastly, HFFS machines are versatile and can accommodate various pouch sizes and styles, making them suitable for different packaging needs.

What are the key features of HFFS machines for tomato ketchup?

HFFS machines designed for tomato ketchup typically include features such as:

-

Accurate Filling Systems: These machines are equipped with precise filling mechanisms that ensure the right amount of ketchup is dispensed into each pouch, minimizing waste.

-

Temperature Control: Since ketchup is a viscous liquid, HFFS machines often have temperature control systems to maintain the product’s consistency during filling.

-

Sealing Technology: Advanced sealing technologies, such as heat sealing or ultrasonic sealing, are employed to create airtight seals that preserve the freshness of the ketchup.

-

User-Friendly Interfaces: Many HFFS machines come with intuitive control panels that allow operators to easily adjust settings and monitor production.

How does the HFFS process work for tomato ketchup?

The HFFS process for tomato ketchup involves several steps:

-

Film Unwinding: A roll of packaging film is unwound and fed into the machine.

-

Pouch Formation: The film is formed into a pouch shape using a series of rollers and molds.

-

Filling: The formed pouch is filled with tomato ketchup using a filling nozzle that dispenses the product accurately.

-

Sealing: After filling, the pouch is sealed using heat or ultrasonic technology to ensure it is airtight.

-

Cutting and Discharge: The sealed pouches are cut from the film and discharged for further processing or packaging.

What are the benefits of using HFFS machines for tomato ketchup production?

The benefits of using HFFS machines for tomato ketchup production include:

-

Increased Efficiency: HFFS machines can operate at high speeds, significantly increasing production rates compared to manual or semi-automatic methods.

-

Consistent Quality: The automated nature of HFFS machines ensures that each pouch is filled and sealed consistently, maintaining product quality.

-

Reduced Labor Costs: With automation, fewer operators are needed, leading to lower labor costs and reduced human error.

-

Flexibility: HFFS machines can be easily adjusted to accommodate different pouch sizes and styles, allowing manufacturers to diversify their product offerings.

Are there any challenges associated with HFFS machines for tomato ketchup?

While HFFS machines offer numerous advantages, there are some challenges to consider:

-

Initial Investment: The cost of purchasing and installing an HFFS machine can be significant, which may be a barrier for smaller manufacturers.

-

Maintenance Requirements: Regular maintenance is essential to keep the machine running smoothly, which can incur additional costs and downtime.

-

Training Needs: Operators may require training to effectively use and troubleshoot the machine, adding to the initial investment.

How can manufacturers choose the right HFFS machine for their tomato ketchup production?

When selecting an HFFS machine for tomato ketchup production, manufacturers should consider the following factors:

-

Production Volume: Assess the expected production volume to determine the machine’s speed and capacity requirements.

-

Pouch Specifications: Consider the desired pouch size, shape, and material to ensure compatibility with the machine.

-

Budget: Evaluate the budget for both the initial purchase and ongoing maintenance costs.

-

Supplier Reputation: Research potential suppliers and their track record in providing reliable and efficient HFFS machines.

What is the future of HFFS machines in the tomato ketchup industry?

The future of HFFS machines in the tomato ketchup industry looks promising. As consumer demand for convenient packaging continues to rise, manufacturers are likely to invest in advanced HFFS technology that offers greater efficiency, sustainability, and customization options. Innovations such as smart technology and IoT integration may also enhance machine performance and monitoring capabilities.

Conclusion

HFFS machines play a crucial role in the efficient production of tomato ketchup, offering numerous benefits such as high-speed operation, consistent quality, and flexibility. By understanding the workings and advantages of these machines, manufacturers can make informed decisions that enhance their production processes and meet consumer demands. If you have more questions about HFFS machines or tomato ketchup production, feel free to reach