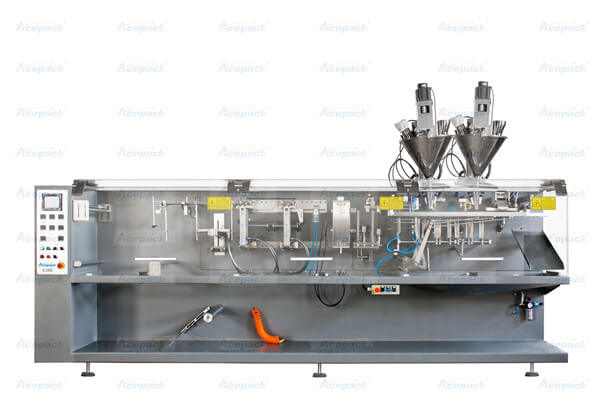

The use of the current powder packaging machine not only makes the packaging of products quick and convenient, but also creates a variety of patterns for packaging, making it more beautiful, and at the same time increasing the competitiveness of the market. Today's powder packaging machine will be more and more effective The bigger, so the operating requirements of the Acepack packing machine company brand powder packaging machine must be more stringent!

The powder packaging machine is one of the packaging machines. It can pack powders, such as milk powder, oatmeal, coffee, etc., to obtain the ideal packaging effect. After the manufacturer purchases the powder packaging machine, it often produces some during use. The problem needs to be solved at this time. Since it is not clear, then listen carefully to our Shanghai Acepack packing machine company to explain the instructions for the powder packaging machine and some precautions.

The first part is the filling part. Before packaging, the material that needs to be packaged should be loaded into the hopper of the powder automatic packaging machine. This process generally needs to be done from the following aspects: 1. Distribute uniformly in the hopper to avoid uneven packaging; 2. Set an appropriate number of feeding bags according to the characteristics of the packaging materials and packaging specifications to ensure stable feeding, and reduce weight changes caused by the impact of feeding to affect measurement accuracy; 3 , If you hear abnormal noise in the silo during work, stop the machine immediately, check the status of the silo, and ensure that there is no foreign matter before you can continue to work; 4. When packaging small sizes, do not put the weighing platform in a place where air flow passes through. , Because it will cause the measurement display to be unstable.

After the filling process is completed, we need to pay attention to the packaging of the materials. This is an important part of the packaging work. It also needs to be carried out in the following steps: 1. Set the parameters of each part according to the equipment manual to ensure the start of work After the accuracy of the packaging is accurate, you can first let the machine try to install it; 2. When packaging work, the operation of the powder packaging machine must be standardized, and do not let the material in the cup and the packaging bag when receiving the material. The materials are squeezed against each other, otherwise, due to the change of the cohesiveness of the materials, it is easy to cause dripping or leakage, resulting in inaccurate measurement or large measurement fluctuations; 3. During the packaging operation of the powder packaging machine, if there are too many materials Do not put it on the weighing table after the second or partial missed connection, otherwise the computer will think that the exact data of the one-time blanking will be adjusted, which will affect the accuracy and speed of the subsequent continuous work; 4. The mouth of the material cup is found during the work. When there is a foreign body, stop and take it out. Note: Do not take the foreign body by hand before shutting down, so as to avoid injury to the body due to the rotation of the photoelectric spiral; 5. Do not swing the spiral horizontally when replacing and cleaning the spiral of the material cup, and avoid breaking the spiral slot Crooked, which affects the next time the screw is fixed and the material cup wears more, which affects the measurement accuracy, and the screw is moved up and down. If it is difficult to remove it, you can loosen the long shaft and take it out together and then take the screw. After finishing repairing the card slot and internal Foreign objects or materials; 6. Do not cover heavy objects on the surface of the sensor, and do not press down. The maximum load shall not be greater than the maximum weighing range, and the sensor shall be placed away from the large vibration source; 7. Replacement of the tight wheel of the powder packaging machine Pay attention to the installation direction and the upper and lower positions of the two thick and thin gaskets when adjusting, and the narrow side of the fixed backing plate of the tensioner is inward, and the upper and lower positions of the gasket are adjusted according to the position of the two driving and driven sprockets. machine.

Next, it is the later work of packaging. Generally, we need to organize and clean the equipment to ensure that the equipment is clean and convenient for next use. I believe that everyone has learned a lot about mechanical equipment such as powder packaging machines. As long as standardized operation can be achieved, and regular maintenance and maintenance can be achieved, the good use of the equipment can be guaranteed, and the ideal effect can be packaged, and the service life of the equipment can be prolonged. Remember, the machine must not be repaired at will And disassembly to avoid unnecessary damage.