Science and technology are advancing more and more, and the rapid development of science and technology has brought great convenience to work. Professional and applicable equipment can make high-speed profits for enterprises, reduce costs and improve work efficiency for enterprises. Professionally purchase equipment applications, understand the actual application range of the equipment, order applicable equipment according to the actual situation, and give play to the practical value of the equipment. With the rapid development of automation and intelligent technology, Shanghai Acepack packing machine company has used more and more bag packaging machines. It is common that the equipment completes its work flow through mechanization and intelligence, which can achieve unmanned workshop management, and it has received more and more attention and favor from the general public in the industry.

Although the advantages of the bag packaging machine are relatively prominent at present, its reasonable operation can bring many benefits to the enterprise, but in the actual operation process, the equipment often has some failures, so Shanghai Acepack packing machine company will related problems Be explained. The common failure modes related to the equipment are as follows: 1. The film material is easy to shift when the equipment is working and cannot be fed normally. How to adjust in this situation? Some factory technicians said that if the film material is shifted in the equipment, the adjustment of the film roll position and the tension balance bar are invalid, the problem can be solved by adjusting the angle of the upper triangular plate. In addition, if the upper film material deviates from the clamping chain, the upper triangle plate can be adjusted clockwise; the lower film material deviates from the clamping chain, and the upper triangle plate can be adjusted counterclockwise. 2. The shrinking machine heats up slowly or cannot rise to a higher temperature. What is the reason for this situation? It is reported that the main power line of the heater goes through a magnetic switch and then to the electric heating tube. Therefore, when the shrinking machine heats up slowly or cannot rise to a higher temperature, first check whether the contacts of the magnetic switch are normal. Generally speaking, if the line does not pass through one of the phases, the above phenomenon will occur; if the magnetic switch is normal, you can check the meter to see if the ohmic value of each phase is the same as that of the machine; if all phases are connected but the line or electric heating If the tube is still abnormal, the heater needs to be replaced. 3. The sealing is uneven or unsealed. The reason for this failure is related to whether the heating time is adjusted well and whether there are impurities on the heating isolation cloth. The user needs to adjust the heating time and heating temperature. If there are attachments on the heating isolation cloth, it should be cleaned and replaced in time to prevent it from affecting normal work.

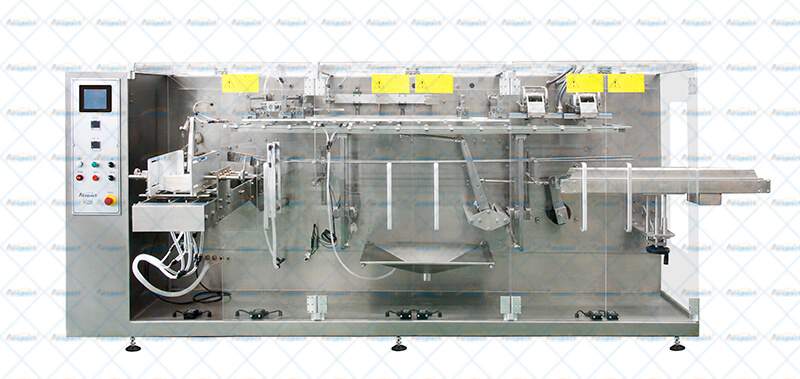

Customers can also add detailed functions such as emergency stop, automatic card insertion, and abnormal discharge according to the packaging needs. The whole packaging process does not require manual operations, which effectively improves production efficiency, saves labor and management costs for the company, and greatly reduces costs . In addition, the Acepack packing machine company brand bag-type packaging machine can also achieve multiple functions in one machine. Users only need to match different metering devices according to different materials to achieve automatic packaging of particles, powder, lump, liquid, and other products!