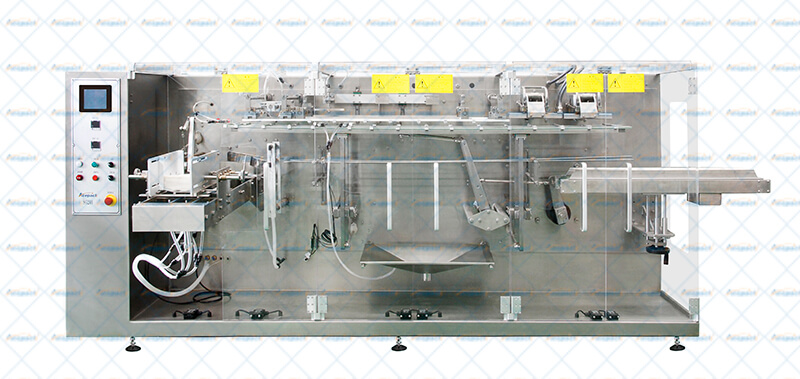

As life gets better and better, the bag

packaging machine replaces manual packaging, and realizes packaging automation

for large enterprises and small and medium-sized enterprises. Operators only

need to make one bag one by one, and hundreds of bags at a time. Placed in the

bag taking part of the equipment, the mechanical grasping of the equipment will

automatically take the bag, print the date, open the bag, give a signal to the

measuring device, and blank, seal and output. Customers can also add detailed

functions such as door opening emergency stop, automatic card insertion, abnormal

discharge, etc. according to product packaging requirements. The whole process

of bag packaging machine packaging does not require labor, which effectively

improves your company's production efficiency and saves labor and management

costs. , Which greatly reduces costs.

We must know the application range of the bag packaging machine. When buying a packaging machine, we must choose the right packaging machine according to what we need. Of course, there are many applications for the bag packaging machine in various industries. The bag-type packaging machine can pack: 1. Liquids: detergent, wine, soy sauce, vinegar, fruit juice, beverage, tomato sauce, jam, chili sauce, bean paste. 2. Blocks: peanuts, jujubes, potato chips, crisps, nuts, candy, chewing gum, pistachios, melon seeds, nuts, pet food, etc. 3. Granules: condiments, additives, crystal seeds, seeds, granulated sugar, soft white sugar, chicken essence, grains, agricultural products. 4. Powders: flour, condiments, milk powder, glucose, chemical seasonings, pesticides, fertilizers.

When we use the bag-feeding packaging machine, we definitely need to know the process. The process of the bag-feeding packaging machine is not particularly complicated and very convenient. 1. Bag loading: the bag is sent to the machine in the way of upper and lower removal. Clip, no bag warning, reduce labor and labor intensity; 2. Print production date: ribbon detection, stop when the ribbon is used up, and touch screen display to ensure the normal coding of the packaging bag; 3. Open the bag: open the bag to detect, not open The bag does not fall to ensure that the material is not lost; 4. Filling material: detection, the material is not filled, heat sealed and unsealed to ensure that the bag is not wasted; 5. Heat sealing: alarm for abnormal temperature to ensure the quality of the sealing 6. Cooling and shaping, Material: to ensure beautiful sealing.