Focus: Buyer's Guide & Technical Specifications

Investing in a spout pouch packing machine requires evaluating technical parameters against operational needs. This guide examines key decision-making criteria for food and pharmaceutical manufacturers.

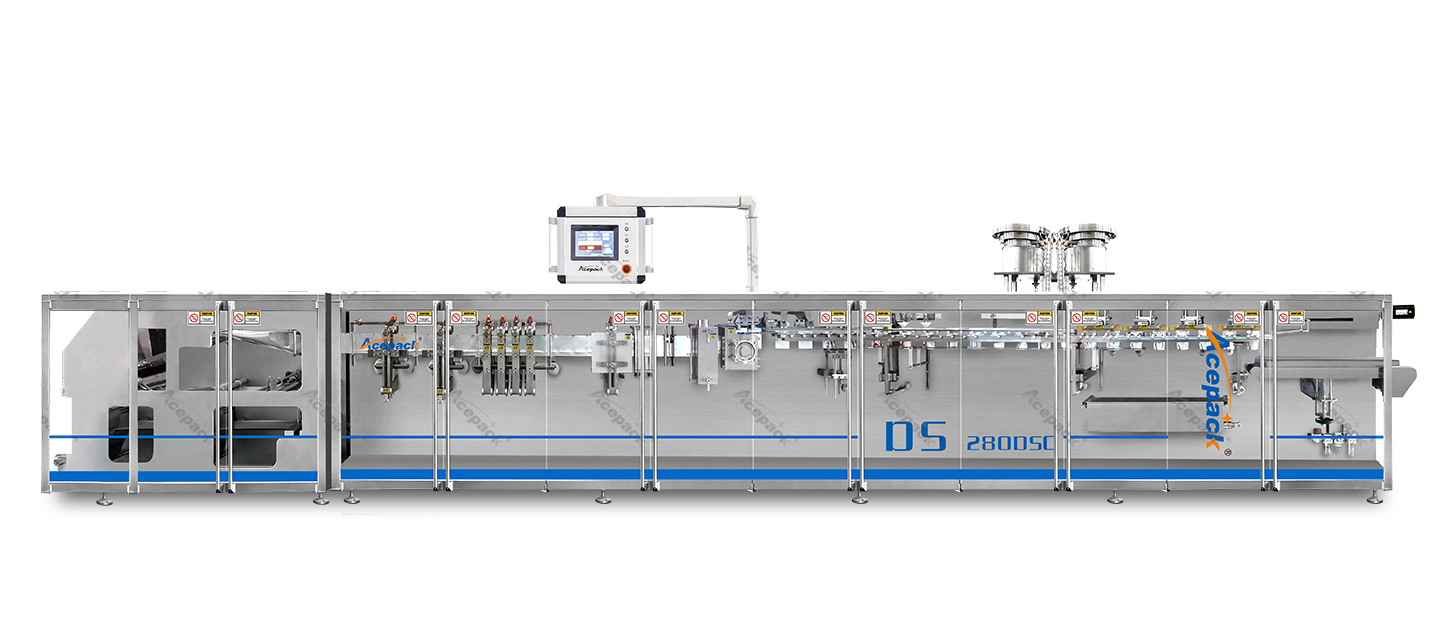

Operational Features to Compare

-

Versatility Metrics

-

-

Pouch size range: Entry-level models handle 100-500ml, industrial units manage 50ml-20L.

-

Film compatibility: Multi-layer laminates vs. biodegradable materials.

-

-

-

Hygiene Standards

-

-

IP69K-rated machines for dairy/pharma vs. standard IP55 for dry goods.

-

Clean-in-Place (CIP) systems reducing downtime by 70%.

-

-

-

Energy Consumption

-

-

Compare kW ratings:

-

Basic model: 5 kW/h

-

Advanced model with servo motors: 3.2 kW/h

-

-

Entry-level Chinese models:

$50,000−$80,000

European CE-certified machines: $200,000+

ROI calculation example:

Output: 40 pouches/min × $0.12/pouch profit = $288/hour

Break-even: 700 production hours

Maintenance Checklist

Daily: Nozzle cleaning with food-grade solvents

Monthly: Conveyor belt tension checks (recommended 20-25 N/m)

Conclusion

Prioritize machines with IoT-enabled predictive maintenance to reduce unexpected downtime by 35%.