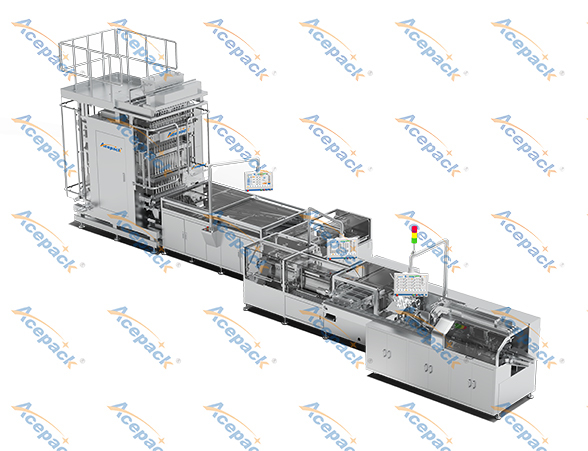

The Acepack multi-lane packaging machine adopts a modular design concept, allowing flexible adjustment of packaging parameters based on different product characteristics. Its core components are made of high-strength alloy materials, ensuring stability and durability during high-speed operation. The unique servo control system enables precise measurement, with packaging accuracy reaching ±0.1%, far exceeding the industry average.

In practical applications, the Acepack multi-lane packaging machine demonstrates significant advantages. For example, a food production enterprise that introduced this equipment saw a 40% increase in packaging efficiency, a 60% reduction in labor costs, and a product qualification rate rise to 99.8%. The machine's intelligent detection system monitors packaging quality in real-time, automatically rejecting defective products to ensure 100% qualification of outgoing products.

The innovative design of the Acepack multi-lane packaging machine is not only reflected in its hardware configuration but also in its industry-leading intelligent control system. The AI algorithm embedded in the equipment can independently learn and optimize packaging parameters, enabling intelligent management of the production process. Remote monitoring and maintenance functions make equipment management more convenient and effectively reduce maintenance costs.