Now to the bag packaging machine to better follow the needs of the enterprise forward, so that the product is more quality assurance, and has a unique appearance, so as to bring more convenience for the enterprise, and in the forward market for you to bring more help. Constantly pay attention to product production so as to bring you new strength, pay attention to the development of the market to make their own strength and production technology to get more improvement, so that their comprehensive strength to get more improvement and bring more competitiveness, to bag packaging machine has good technology and quality so as to get more consumers love.

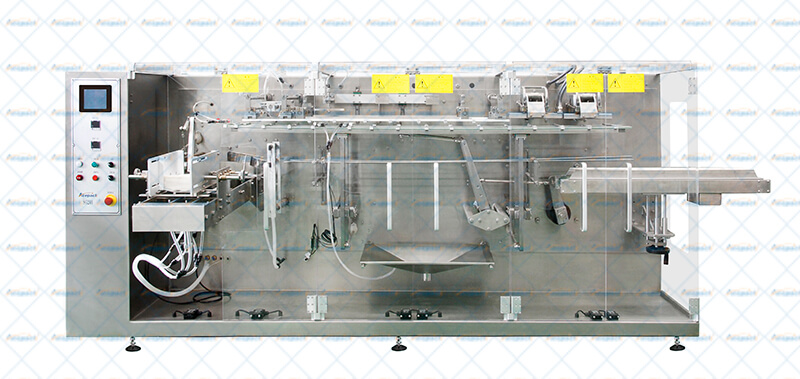

Bag packing machine is a very important link in the industrial production process, not only can protect the safety of products, but also can pull up the appearance of the product level, improve customer experience, and give bag packaging on these basis for improving the production efficiency of enterprises, reduce labor intensity, reduce production costs and play a great role. Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. to introduce you, the details are as follows:

1. Improve labor productivity

Mechanized packaging compared with artificial packaging a major advantage, is to improve efficiency.

2. Effectively ensure packaging quality

Mechanical packaging can be packaged according to the requirements of the goods, in accordance with the required shape, size, to get the same specifications of packaging, which is not guaranteed by manual packaging. This is particularly important for export commodities, only mechanical packaging, can achieve packaging standardization, standardization, in line with the requirements of collective packaging.

3. Reduce labor intensity

To improve the working conditions, the labor intensity of manual packaging is very large, such as the use of manual packaging of large volume, heavy products, both physical energy consumption, and unsafe; For light and small products, because of the higher frequency, monotonous action, easy to make workers suffer from occupational diseases. The addition of mechanical packaging equipment can reduce the labor intensity of workers and relieve their working pressure.

4. Ensure product hygiene

Some products such as food and medicine packaging, according to the health law is not allowed to use manual packaging, because it will contaminate the product, and mechanical packaging to avoid direct human contact with food and medicine, to ensure the health of the product quality.

Welcome to consult Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. Oh!

Acepack (Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd.) is a high-tech enterprise specializing in the design, development, manufacturing, sales and service of fully automatic packaging machine, intelligent packaging production line and intelligent packaging system. Shanghai Acepack packing machine company Packaging Machinery Co., Ltd, the predecessor of the company, was founded in 2005. Adhering to the development concept of "Craftsman Innovation, Intelligent Transformation", it was renamed Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd in 2017. Since its establishment, from traditional packaging to intelligent manufacturing, Acepack has always been adhering to the values of innovation, learning, integrity, unity and win-win, with the quality concept of focus and responsibility. The products are used in many fields such as pharmaceutical, food, daily chemical, health industry and so on, and are exported to more than 50 countries and regions worldwide. Acepack is committed to building an international brand of intelligent packaging system and creating packaging value for global customers by means of the collaborative development of innovative technologies in multiple fields, no matter from the needs of end users or the industrial end.

Contact person: Manager Liu Tel: 18017198016