At this stage, the development of enterprises is very fast, in order to

meet the growing market demand, the production enterprises are increasing the

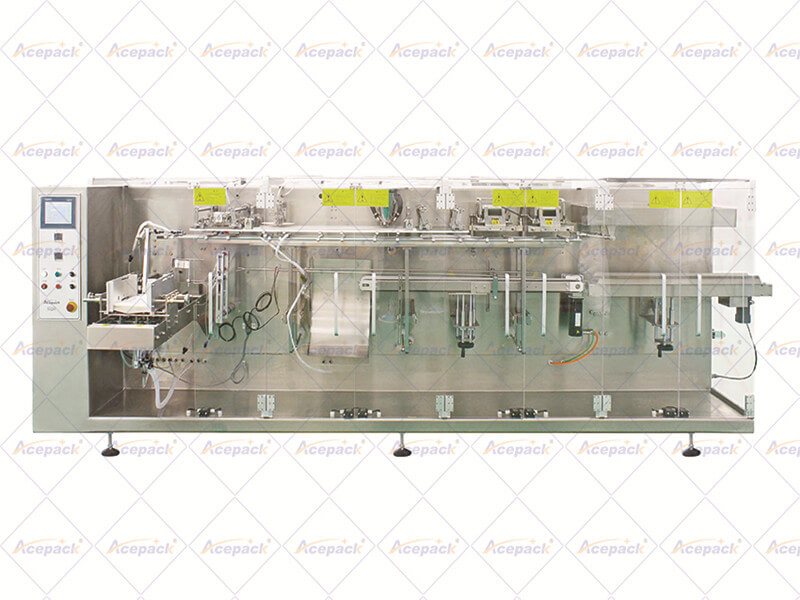

application of new technology and new equipment. Automatic bag packing machine

instead of manual packaging, can package liquid and paste such as shrimp slip,

solid particles such as nuts, candied fruits, lumps such as pig's feet and duck

wings. Packaging automation is realized for large and medium-sized enterprises.

As long as a staff member puts hundreds of good bags in the bag taking

department of the equipment at one time, the mechanical claw of the equipment

will automatically take out the bags, print the date, open the bags, signal the

metering device, and drop, seal and output.

The specific packaging process of the machine is: one on the bag, two open the bag, three fill material, four seal, five print production date. Like this kind of automation, intelligent, production efficiency, production quality, full-featured, high-tech content of the full-automatic bag packaging machine to more meet the production needs of enterprises.

The machine adopts advanced computer electrical control system, friendly man-machine interface, convenient operation, and is equipped with detection device, which can check that the filling device does not fill and the heat sealing device does not seal when there is no package or the package bag is not opened, so as to avoid waste of packaging materials and raw materials.

1. It can bear greater work pressure, can bear high-yield job requirements, but workers can not, if all-weather work, long-time staff will reduce work efficiency, shift system will increase labor input and cost investment!

2. Labor saving, the working process of automatic bag type vacuum packaging machine is completed by mechanical equipment, which can save manual operation for enterprises and solve the problem of recruitment difficulty in today's society.

3. The work efficiency is incomparable with the traditional manual, because the mechanization of the equipment will not appear fatigue, and does not need manual operation, so compared with the traditional manual packaging, its work efficiency is higher.

4. The operation is convenient and fast. It is controlled by intelligent control system. It can complete multiple processes at one time: automatic bag taking, coding, opening, filling, vacuuming and sealing.

5. The machine can be used in many ways! The bag width and sealing position can be adjusted at one time, which provides convenience for enterprises to package various types of products, saves operation time and improves production capacity.

This kind of packaging machine has replaced manual packaging and has become a powerful assistant in the packaging production line. Compared with the general packaging equipment, the current automatic bag feeding packaging machine is a more classic processing equipment. Low production cost, mass production, to a large extent, to meet the enterprise's high output, high quality production tasks. Help the rapid development of enterprises. Major enterprises for the automatic bag packaging machine technology are very recognized.

With the continuous improvement of the bag packaging machine technology, this machine is recognized by more and more food enterprises, and is more applied to the production of enterprises. I hope this article is helpful to you!