Good product quality and good product appearance are equally important, which is the due progress of market development. With the improvement of people's quality of life, more and more attention is paid to the appearance of fully automatic packaging machine products. A good-looking appearance can better attract the attention of consumers and better promote the sales of products. Some food production enterprises in the development, is blindly pay attention to the improvement of product quality, but ignore the packaging of products. Although good quality is necessary, but good packaging can make our products more perfect, to be consistent inside and outside.

Automatic packaging machine is more and more widely used in the food industry. In the process of using the automatic packaging machine, good operation technique has a great relationship with the use of the product. If the improper use of the automatic packaging machine not only affects the use effect of the product, but also shortens the service life of the equipment. Then how to operate the automatic packaging machine correctly? Next, let's explain it in depth!

1. Before starting the machine, we should first check whether the pressure of the compressed air meets the requirements, and check whether the main parts are intact, such as heating belt, scissors, car parts, etc. At the same time, check whether there are other people around the machine to ensure the safe use after the boot.

2. The operating personnel shall not adjust the machine to run some parameters, such as run number, servo, and the various parameters of the frequency conversion to adjust, must report to chief of a section, by the related maintenance personnel or technical personnel adjustment, production, according to the actual situation, operators can temperature and part of the phase Angle of each temperature controller parameters are adjusted, but must first notify the leader and the chief of a section, to ensure the whole process all parameters of the equipment operation is controlled, to ensure the stable operation of the equipment, guarantee the normal production and product quality.

3. Fill oil lubrication for all gear meshing places, bearing holes and moving parts of the automatic packing machine on time. When filling lubricating oil, please be careful not to drop oil on the transmission belt, in case of slipping and loss or belt aging damage.

4. Operators can only use clean fingers to gently touch the touch screen. It is strictly prohibited to press or tap the touch screen with fingertips, fingernails or other hard objects.

5. When debugging the machine or adjusting the bag-making quality, the quality of bag opening, the filling effect, the trolley bag unfolding and the bag receiving can only be debugged by manual switch. The above debugging is strictly prohibited when the machine is in running state to avoid the occurrence of safety accidents. Whenever a relatively large fault needs to be debugged and handled and to open the CAM box to adjust the CAM or change the spring, it must first hang the "maintenance, no boot" safety warning board at the touch screen of the machine operation. At the same time, anyone who sees a safety warning board in everything shall not start the machine at will.

6. Before replacement, check whether the products made before are finished and make sure there is no packaging residue in the chain; The order of disassembly and installation must be observed from bottom to top, first disassembly and then assembly to replace the product molds. After the replacement procedure, the height of the chain conveyor belt must be adjusted to the reference index of the equipment.

7. During the maintenance of the equipment, the sudden start of the equipment should be prevented. It must be understood that the stop switch is only to cut off the power supply or the motor starter. For the sake of ensuring, the power switch on the equipment distribution board should be cut off and the maintenance sign should be hung up. Before starting the equipment, check and confirm it, and contact the relevant personnel before starting the equipment.

Remember these warnings, your automatic packaging machine will certainly increase the service life, will also reduce the occurrence of failure rate, improve production efficiency these are not a big problem. Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. teaches you the correct operation method, I hope to help you when you pack products.

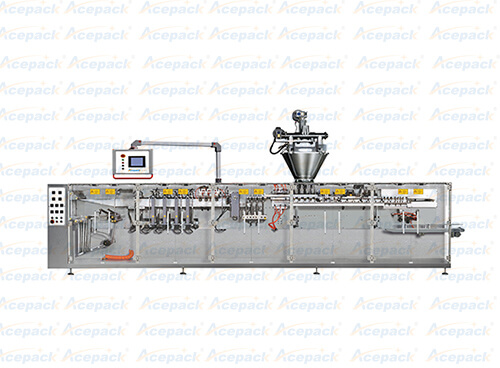

ACEPACK (Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd.) is a high-tech enterprise specializing in the design, research and development, manufacturing, sales and service of automatic packaging machines, intelligent packaging production lines, and intelligent packaging systems. The company's predecessor is Shanghai Acepack packing machine company Packaging Machinery Co., Ltd. The company, founded in 2005, adheres to the development concept of "craftsman innovation, intelligent transformation", and was renamed Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. in 2017. Since its establishment, ACEPACK has always been adhering to innovation, learning, and The core values of integrity, unity and win-win, with the quality concept of professionalism, focus, extreme, and responsibility. Products are widely used in many fields such as pharmaceuticals, food, daily chemicals, and health industries, and are exported to more than 50 countries and regions around the world Regardless of the needs of end users or the needs of the industry, we will rely on the collaborative development of innovative technologies in multiple fields to build an international brand of intelligent packaging systems and create packaging value for global customers.

Contact: Manager Liu Tel: 13917335813