With the improvement of social and economic standards, people's consumption outlook and consumption habits have changed, and packaging regulations have become higher and higher. The bag packaging machine is warmly welcomed by customers. In order to better respond to the development of social development Trends, packaging companies continue to innovate machinery and equipment. In recent years, bag-to-bag packaging machines for manufacturing and product development can not only reduce labor costs, but also increase the production capacity of processing plants.

In the bag-type packaging machine market, competition is also quite strong. The bag-type packaging machine replaces manual packaging, which can pack liquid, block, granule, powder, and realizes packaging automation for large and medium-sized enterprises, as long as one The staff put hundreds of finished bags in the bag taking part of the equipment at one time, and the mechanical grasping of the equipment will automatically take the bags, print the date, open the bags, give the metering device signal to measure, blank, seal, and output. It is also possible to add detailed functions such as door opening emergency stop, automatic card insertion, and abnormal discharge according to product packaging requirements, which effectively improves your company's production efficiency, saves labor and management costs, and greatly reduces costs.

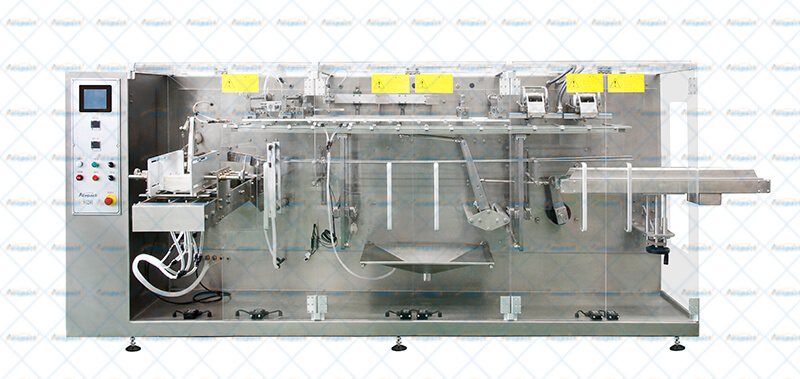

Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. gives the bag packaging machine performance: 1. Convenient operation, using PLC control, with touch screen man-machine interface control system, convenient operation 2. Frequency conversion speed regulation, this machine uses frequency conversion speed regulation device, in The speed can be adjusted freely within the specified range. 3. The automatic detection function, if the bag is not opened or the bag is incomplete, no feeding, no heat sealing, the bag can be reused, no waste of materials, saving production costs for users. 4. Safety The device will give an alarm when the working air pressure is abnormal or the heating tube is faulty. 5. The horizontal bag feeding mode, the bag storage device can store more packaging bags, and the quality of the bag is lower, and the bag splitting and bag loading rate is high. 6. Adjusting the bag width is controlled by a motor. Press and hold the control button to adjust the width of each group of machine clips at the same time, which is convenient to operate and save time. 7. The packaging material loss is low. This machine uses prefabricated packaging bags and packaging bag patterns. Perfect, the sealing quality is good, thus improving the product grade. 8. In line with the sanitary standards of the food processing industry, the parts on the machine that are in contact with the material or the packaging bag are made of stainless steel or other materials that meet the food sanitation requirements to ensure the sanitation and hygiene of the food. Safety. 9. Wide range of packaging. By choosing different meters, it can be suitable for the packaging of liquids, sauces, granules, powders, irregular lumps and other materials. 10. Packaging bags have a wide range of applications, and are suitable for multi-layer composite films. Prefabricated bags and paper bags made of materials such as, silica, aluminum foil, single-layer PE, PP, etc. can be used.

Shanghai Acepack packing machine company Intelligent Packaging Technology Co., Ltd. is one of the choices you buy for the bag packaging machine. If you have any needs, please feel free to consult!!!