With the rapid development of food industry, food packaging machine ushered in market increment. The large use of packaging machinery and equipment in China not only improves the efficiency of packaging, but also improves the level of packaging industrialization in China to ensure the quality of packaging. At the same time, it plays a great role in improving the working conditions of workers and saving labor costs. Obviously, the user needs reasonable operation after purchasing the equipment, which not only ensures the normal operation of the equipment, but also ensures the service life of the equipment. So, how to use and operate food packaging machinery and equipment?

With the rapid development of food industry, the related food packaging machinery and equipment also ushered in good development opportunities. However, for users, in the process of using the equipment, it is necessary to use the operation reasonably, reduce the occurrence of faults and ensure the stable operation of packaging machinery and equipment.

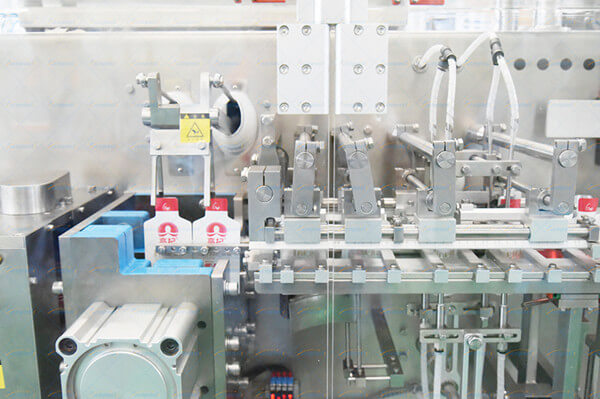

Reasonable installation and operation of equipment is the premise to ensure the stable operation of packaging machinery and equipment. Industry insiders pointed out that packaging equipment in the process of work, must put reasonable installation, operation to an important position. Because some places are easy to be ignored by operators, sometimes the equipment will break down or even face the risk of shutdown. Therefore, it is necessary to attach great importance to ensure the safe and stable operation of the equipment.

In fact, any packaging equipment has standard operation requirements. If the equipment is not operated properly and pay attention to relevant matters, even if the equipment failure will not occur in a short time, the failure rate of the equipment will be increased. So, how to reasonably install and operate packaging machinery and equipment to ensure the stable operation of the equipment?

Food packaging machinery and equipment operation need to pay attention to these aspects. First, insert the machine wire plug into the AC power socket, turn on the overall system of the machine circuit and connect the circuit of the whole machine. Second, the bakelite mold is placed on the mold platform, and the wire on the bakelite mold is connected with the bakelite mold terminal in the middle of the machine mold table. Third, turn on the cooling switch, turn on the cooling time control circuit, adjust the button when setting the cooling time, and select the pressing time of pressing plate. Fourth, the user can choose the appropriate heating current gear according to the actual packaging situation.

Not only that, in the process of packaging production, because the device of sealing and cutting film belongs to high temperature, users are not allowed to touch the hot sealing wheel, sealing mold and moving parts at will to prevent scalding. In addition, it is also forbidden to put your hair, gloves and clothes into the moving parts, so as to avoid accidents caused by being involved. Finally, users also need to carry out regular inspection, cleaning and lubrication maintenance work for each packaging machine. What's more, we should also do a good job in heat dissipation and ventilation. Do not put the packaging equipment in high temperature, humidity and dirty use, which can not only prevent the components from being damaged quickly and the products from being polluted, but also prevent the equipment performance from being affected, thus affecting the follow-up work efficiency and service life of the equipment.

If you want to know more about food packaging machine, you can ask us Shanghai Acepack packing machine company Intelligent Packaging Co., Ltd., we will give you the right choice.